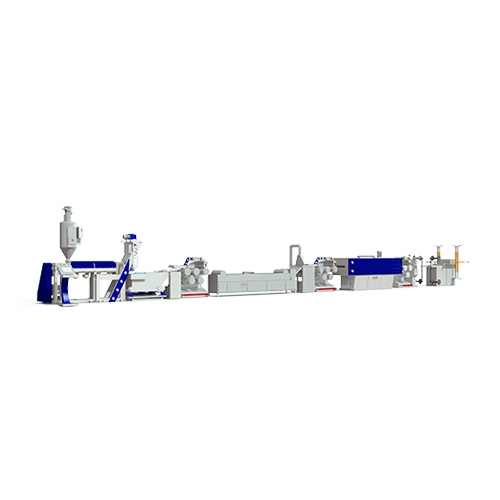

PET吹瓶机系列-TEM06M1

产品分类 : 自动吹瓶机

特点采用64K彩色触摸屏控制系统,PLC操作友好。独特设计的机器结构使将吹塑机与输送机系统结合起来非常方便。瓶胚是自动的。特点采用64K彩色触摸屏控制系统,友好的PLC操作。独特设计的机器结构使将吹塑机与输送机系统结合起来非常方便。瓶胚自动排列,以便以单一方式供料,分料架由伺服电机驱动;这样可以避免瓶坯卡住,机器掉落或瓶坯浪费。采用伺服控制螺杆驱动系统;它是快速,稳定,清洁和环保的。将预成型坯以矩阵模式送入加热系统,并通过单灯和双面加热均匀加热。采用带有双面加热设计的单灯,与竞争对手的方法相比,将节省约50%的热量消耗。具有温度反馈功能,通过调节红外灯自动控制加热炉中的温度,以减少预结晶的问题。特殊设计的加热箱可提高更换红外灯和冷却坡道的维护便利性。夹紧机构由伺服电机和凸轮驱动。这样可以实现准确而稳定的运动,低噪音和最小的污染。利用空气回收系统,效率高达50%,因此不需要低压空气压缩机。这样可以节省设备投资成本和能源消耗多达15%。按单向进给系统布置,分隔架由伺服电机驱动;这样可以避免瓶坯卡住,机器掉落或瓶坯浪费。采用伺服控制螺杆驱动系统;它是快速,稳定,清洁和环保的。将预成型坯以矩阵模式送入加热系统,并通过单灯和双面加热均匀加热。采用带有双面加热设计的单灯,与竞争对手的方法相比,将节省约50%的热量消耗。具有温度反馈功能,通过调节红外灯自动控制加热炉中的温度,以减少预结晶的问题。特殊设计的加热箱可提高更换红外灯和冷却坡道的维护便利性。夹紧机构由伺服电机和凸轮驱动。这样可以实现准确而稳定的运动,低噪音和最小的污染。利用空气回收系统,效率高达50%,因此不需要低压空气压缩机。这将节省设备投资成本和能源消耗多达15%。

CONTRACT ASSEMBLY

Our Electronic Manufacturing Service (EMS) is used to Co- design, test, manufacture, distribute and provide repair services for electronic components and assemblies for Original Equipment Manufacturers. We have provided Co- design engineering and contract EMS for the consumer electronics, industrial, medical, military and telecommunications markets. We specialize in a variety of contract assembly levels from high volume, complex electro-mechanical assembly & testing to small volume, conceptual prototype runs. For small to medium device assembly, we utilize a cost savings system of mobile workstations and conveyors that can be quickly grouped into private and secure assembly cells. MANUFACTURING CAPABILITIES Electromechanical Assembly Subassembly and/or Final Product Assembly RoHS Compliant Assembly Lean Manufacturing PLM, MES, QMS, System Dedicated Program Management Functional and Post-Assembly Test Verification Material Procurement and Consigned Management FACILITIES 10,000 & 100,000 class clean rooms Flexible cell production system Mass management with Manufacturing Execution System (MES) 30,000 sq ft floor space with room for expansion Large, medium or small minimum order quantity (MOQ) HR expertise to maintain qualified production workers 24/7 operations SUPPLY CHAIN MANAGEMENT SERVICES YOMURA TECHNOLOGIES has many years of material & component sourcing experience and has direct relationships with factories around the world. Our office has been designed to coordinate quick quotes, provide constant updates and track all data needed to communicate with and expedite all client orders. This ensures a smooth transition from placement of orders to delivery. We understand our clients need to keep inventory levels low to control costs, yet still need to respond quickly for new orders to satisfy your customer demand. Clients can leverage our supply chain management expertise to receive volume quality products without high inventory risk. By customizing our stocking and logistics programs to meet your production needs we can reduce your material inventory during all stages of development from prototypes all the way through high volume production orders. TEST ENGINEERING Our Test Engineering department is staffed with experienced engineers and technicians who excel at working with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, identify failures early, support root cause analysis, and assist design engineering with test analysis. Yomura has more than15 years waterproof IP68 test. REWORK SERVICES Sometimes rework of existing product assemblies is necessary to fix a design flaw, upgrade an assembly with a new components, or simply to find a cost down solution. Our rework specialists assure that resulting assemblies will meet the highest quality standards. CERTIFICATIONS QUALITY SYSTEM AS9100 / ISO 9001 / ISO 14001 / ISO 13485 / TS 16949 / UL Compliant / FDA / MFi