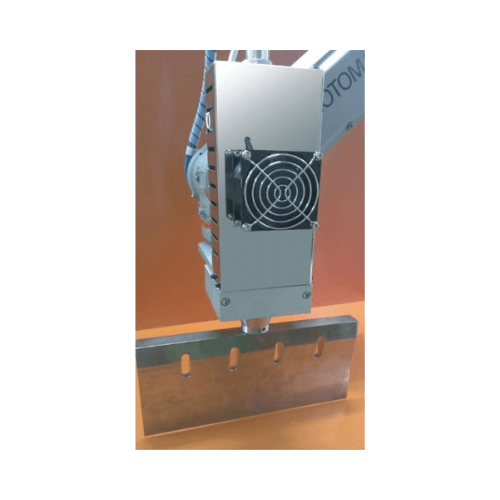

Ultrasonic Module for Food industry-Ultrasonic Food Cutting Module

Auto Frequency Tuning Ultrasonic System

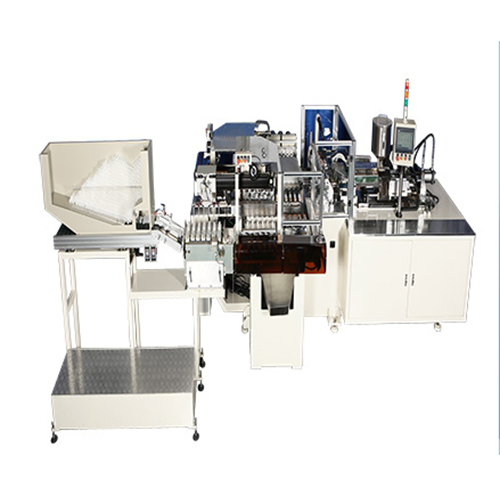

1出6水平接头机RIH-60-06

产品分类 : 压板注塑机

人机介面操作控制。可进行椭圆管与圆形管生产。模具可进行自带孔产品模具设计。全自动伺服控制: 进/退管系统、钻孔(选配)、切头(选配)、选点(选配)。储料箱+输送带式自动送管。四分割工作站。

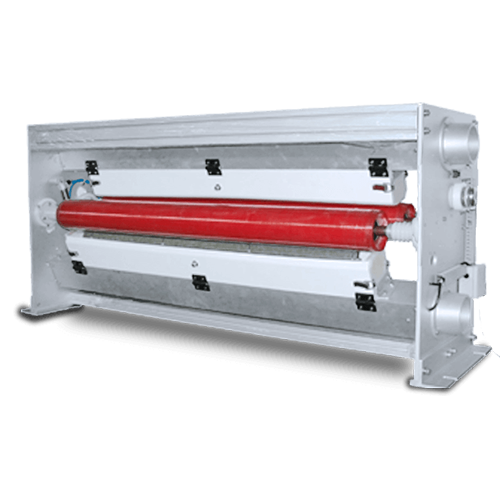

TE-A 电晕处理机

产品分类 : 表面处理设备

高速三层吹膜机用 LDPE/HEPE/PP/EVA/NYLON 主机 2KW~10KW 处理宽度600~2000MM 双面处理 不锈钢2mm片式放电刀

欧化立式混合机SVM-U

产品分类 : 搅拌机和搅拌机

本系列机型主要用于塑胶的混合搅拌,如原料与色母及回收料等多种原料的混合作业,但不可用于各类塑胶粉末原料的混合及各类食品、化学药品、易燃易爆及挥发性物品的混合。若塑胶原料切片尺寸不均匀或为其他形态时,需要考虑原料堆积比重。

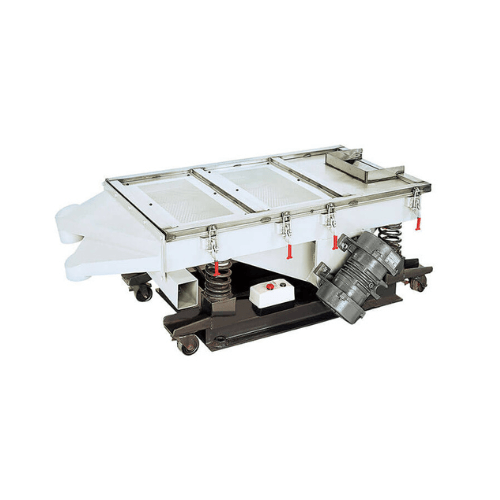

Vibrating Screen

产品分类 : 分离器

The CYKF Vibrating Screen is used for sorting plastic pellets. It divides the pellets discharged from pelletizer. The machine can be combined with our strand pelletizing or underwater pelletizing extrusion lines.

TC5V 阀门控制器-2段

产品分类 : 控制设备

输入讯号选择( AC220 / 110 / DC24 / 开关式) 输出模式选择( AC220 / 110 / DC24 / 开关式) 时间显示可调至小数点第一位时间计数可选择累加或倒数三种控制模式选择可选择保压模式电子式开关延长使用寿命( 电流可达600 mA ) ( 标准) 可选用机械式开关,输出电流较大( 选配) 长新

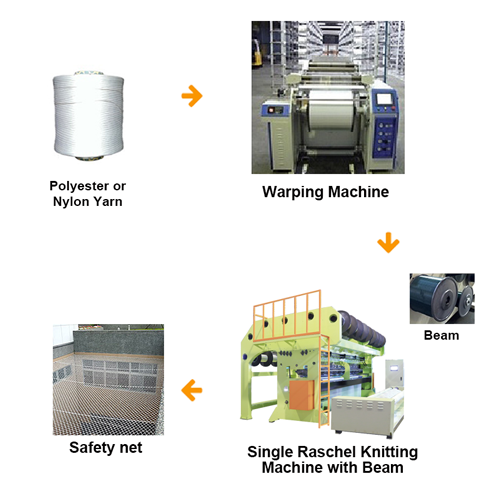

安全网

产品分类 : 工业针织机

Fishing net making machine of SR-KF Series is single needle bed Raschel knitting machine designed for making knotless fishing nets with various specifications in all different kinds of raw material; for example, Nylon, PE, PP, etc. The control panel of this series adopts inverters or servo motors to control speed, easy for machine operation and adjustment.

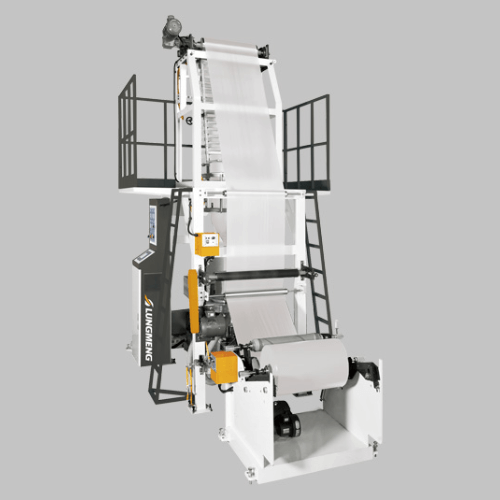

吹袋押出机螺杆/料管

产品分类 : 螺杆与机筒

吹膜挤出的核心是螺杆部分,南允设计的吹膜挤出机的螺杆和机筒能够以符合处理器产量目标的速率提供优化开发的聚合物熔体。此外,我们为吹膜厂或吹塑机设计的螺杆和机筒在熔体质量、熔体温度和规格均匀性方面也有出色的表现。

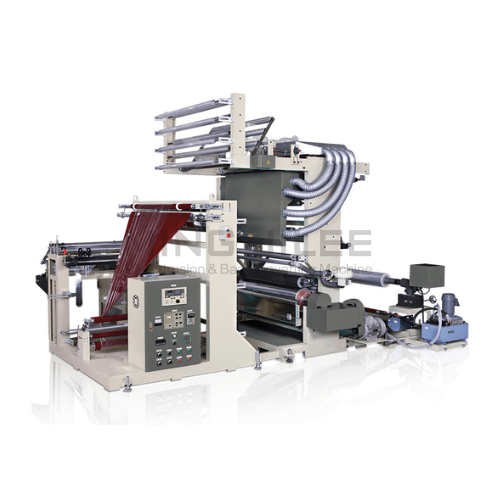

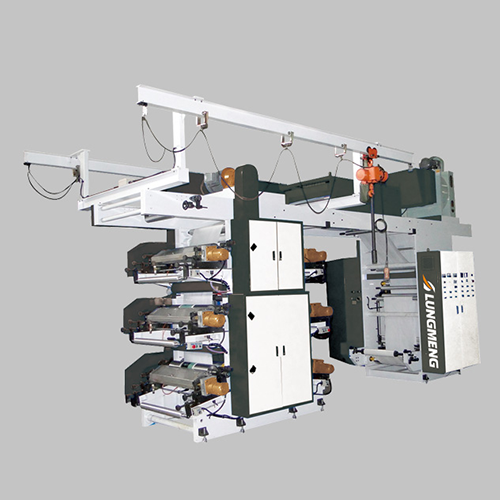

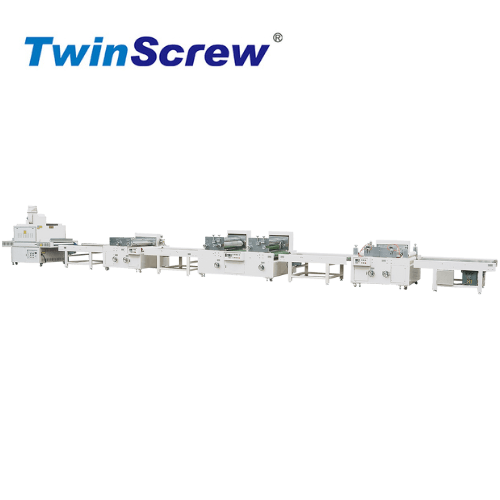

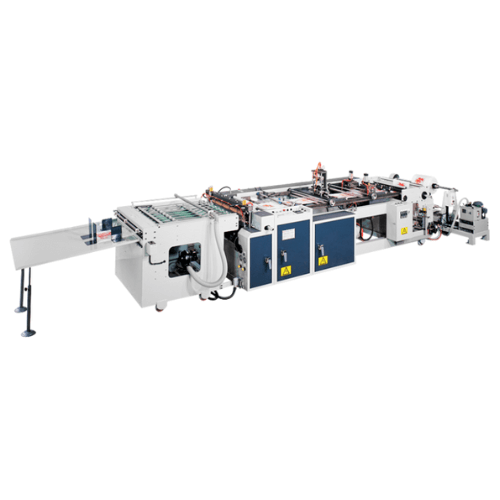

PVC Wood-Grained Printing & U.V.Curing Equipment

产品分类 : 挤出涂布机

One line equipment includes a conveyor, U.V. curing machine, U.V. coating machine, 3-colors wood-grain printing machine, and wash-out machine, we can meet customers' requirements in choosing the suitable machine.

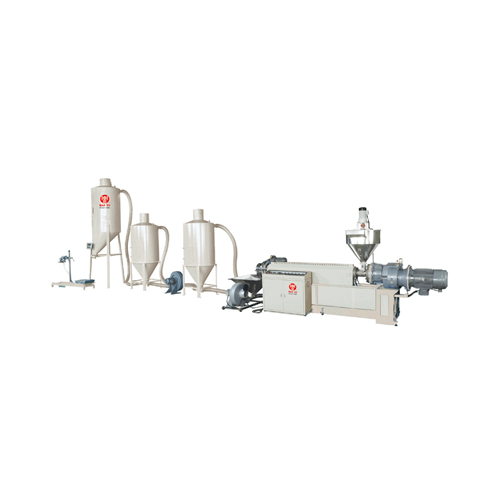

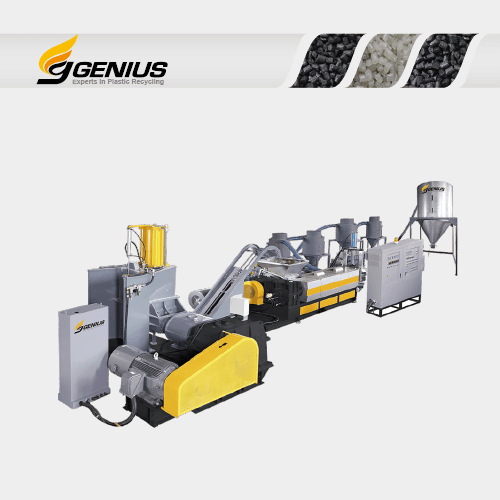

HF-FTO 三合一塑胶废料再生制粒机

产品分类 : 塑料造粒机

主要应用于蓬松的废塑胶回收,经由破碎、挤出过滤、造粒,为客户提供客制化的废塑胶回收解决方案。依物料特性差异,包括了针对薄膜、纤维、粉碎块料、粉碎片材回收再利用,要求高产量的强制入料规划单螺杆造粒生产线,以符合客户生产需求为目标。适用材料: PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、ABS

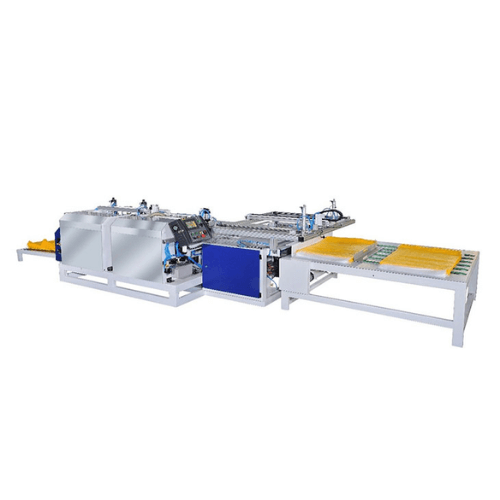

Bag Top Hemming Machine For PP Woven Bag (Bag Top Finishing Process) Model No: Top-Hem

产品分类 : 无纺布生产线

With Liner Inserted Bag / And Also Normal Bags Without Liner Insertion. With Laminated Woven Fabric /And Also Non-Laminated Woven Fabric.

碳酸钙混练造粒整厂设备

产品分类 : 复合线

1.动力传动系统:采用高扭矩齿轮箱,马达输出时较省电。 2.押出机附有压力感测计,压力过大即亮警示灯或蜂鸣器通知更换滤网。 3.填料母粒可和多种塑胶原料混合,并依照产品的不同特性分散加工,制成高浓度的粒子。 4.适用物料:PP, LLDPE, LDPE, PLA, EVA, and PVC 等回收塑料。 5.适用添加在生产塑胶制品中,最高碳酸钙添加比例80%~90%。

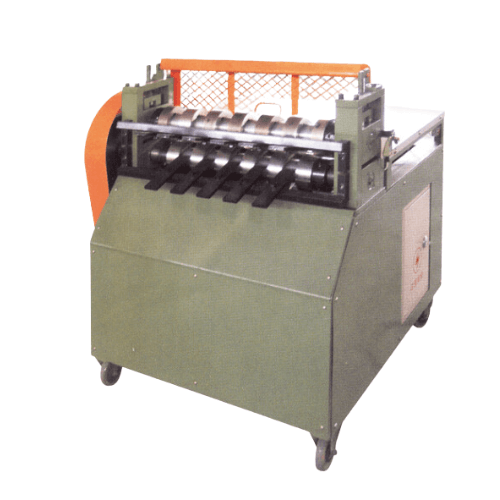

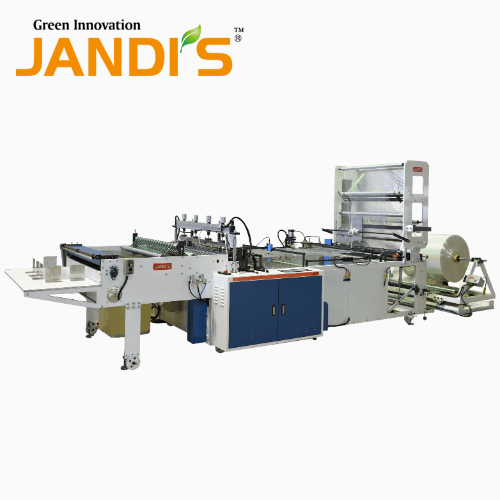

无拉力底封厚袋制袋机 (三套伺服马达) LY-650BF/LY-800BF/LY-1000BF

产品分类 : 切割机

Introduction LY-650BF/800BF/1000BF series are free-tension heavy duty bag making machine, its 3-sets servo control system allowing customer to make very thick bag with good quality of sealing. All series have HMI system for easy operation. Features Free-tension, heavy -duty bottom sealing bag making machine. Servo-driven feeding system with one set of photocell for printed bag. Servo-driven flying knife system for cutting. Servo-driven sealing bar for good quality of sealing. Human-machine interface for easy setting.

淋膜机

产品分类 : 工业复合机

PLC STATION 1 - Laminating speed control - Extruding speed setting - Laminating parameter setting - Operation temperature setting - Driver status monitoring - Production additives saving - Malfunction warning information - Tension information monitoring PLC STATION 2 - Automatic unwind tension control - Diameter detecting control - Dancer roller tension control - Automatic cutting roll change - Jointing gluing surface check - Automatic pre-drive jointing - Automatic infeed tension control - E/P transducer control PLC STATION 3 - Automatic rewind tension control - Rewind tape tension control - Dancer roller tension control - Automatic cutting roll change - Non-stop roll change - Automatic length counting - Automatic outfeed tension control - E/P transducer control

PVA Water Soluble Side Sealing Bag Machine - GF-S1000/SV

产品分类 : 塑料制袋机

This bag making machine is also available for the manufacturing of biodegradable bags.

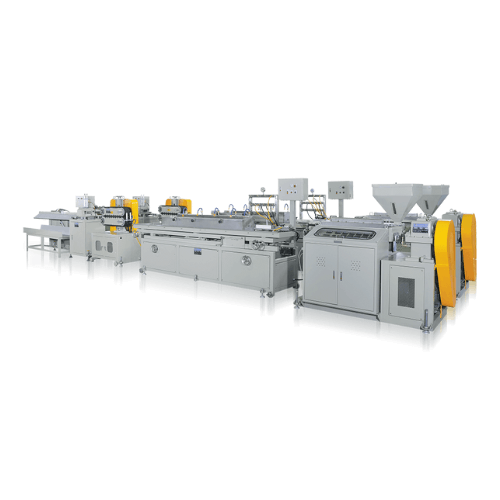

WPC PROFILE EXTRUSION LINE - PE/PP/PS/TPE/PVC

产品分类 : 管材与型材挤出生產线

The WPC profile extrusion line is a set of machines used in the production of WPC boards. Differences between WPC profile extrusion and general profile extrusion WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products. How does WPC profile extrusion line work? The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product. Advantages of WPC profile extrusion line Efficient and consistent production of high-quality WPC profile products. The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties. Highly automated, reducing the risk of human error and increasing efficiency. Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.