Tape Line Jumbo Making Machine-TY-TLJM Series

产品分类 : 长丝与纱线挤出生產线

TLJM series is mainly used in PP & HDPE high denier tape production, it used for weaving by circular loom and flat loom into tubular jumbo bags, FIBC fabrics, tents, geotextiles and waterproof tarpaulin.

WASTE TYRE RECYCLING

Reasonable budget and friendly operation Waste Tyre Recycling System with best quality from Taiwan Because of the many grades of the end product and the wide variety in the choice of machinery we are in a position to offer our services in the design, selection, supply, erection and commissioning of complete plants or single machines based on the specific regional and economic conditions. In order to reduce the wear and increase the life time of knives, ChangWoen has designed a three-stage processing technology (pre shredding, granulating, fine grinding) with much economical solution which ultimately produces vary high-quality materials for recycling. Against of shredding entire tyre with steel get rid of steel bead in the beginning of process and that leads to a economical way to I increase the life of knives by 30% more rather than without De-Beading Machine.

多轴自动贴膜机AFC-700LE

产品分类 : 切割机

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

HP-45-45-45-3L-X

产品分类 : 吹膜挤出机

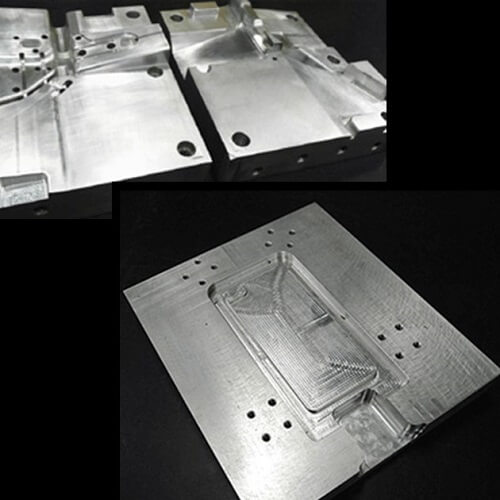

SOFT TOOLING

产品分类 : 热流道系统

For small production runs or for prototyping, soft tooling is a fast and low cost way to build multiple copies of your product. To provide quick mold soft tooling services our engineers were sent to Japan to learn from soft tooling experts. MATERIALS: Cavity & Core Insert Made from Aluminum or Steel, Mold base free ADVANTAGES: Low Cost & Short Lead Time (5-10 days) Useful for R/D testing and trail runs, reduces final tooling risks Can product approximately 500 Shots DISADVANTAGES: Soft tooling will cycle slower due to poor thermal conductivity of mold material. Material life of soft tooling is limited and will depend upon part complexity. Our mold fabrication shop is equipment with high-end Charmilles EDM and OKK CNC machines. Please visit our Mold Fabrication page for more details.