高精度小尺寸自动裁断生产线-APL-300

产品分类 : 发泡机械

●伺服裁断机构: 裁断主轴采用伺服马达控制,高效率,高精度。 ●自动送料机构: 采用高阶伺服控制,送料速度快,定位精准。 ●与多轴自动贴合机连线: 与RAL-400高精度多轴自动贴合机连线作同步加工。 ●与自动切片机连线: 与AC-300小尺寸切片机连线作切片加工。 ●二次加工对应: 可对应双站对位裁断加工。

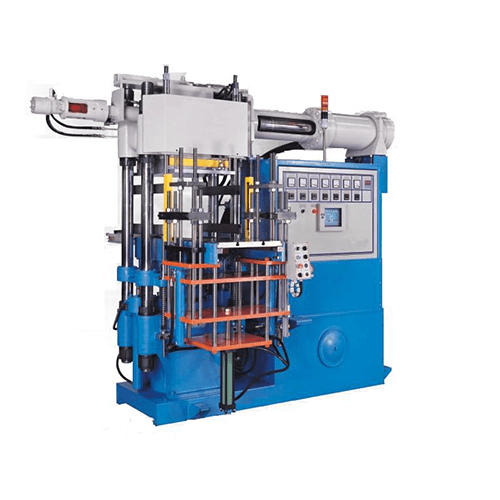

2RT开模轮胎胶囊专用橡胶射出成型机

产品分类 : 橡胶注射成型机

产品特性开模设计当模具出模时,前顶油压缸会顶出模芯并且吹气,使胶囊充气脱模,方便操作者拿取成品。射出量控制采高精密度光学尺设计,能准确的控制与计

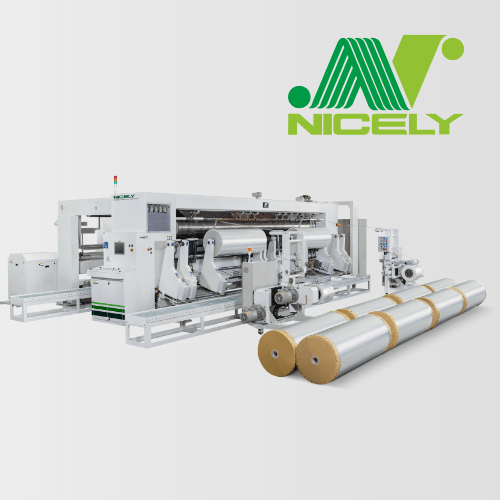

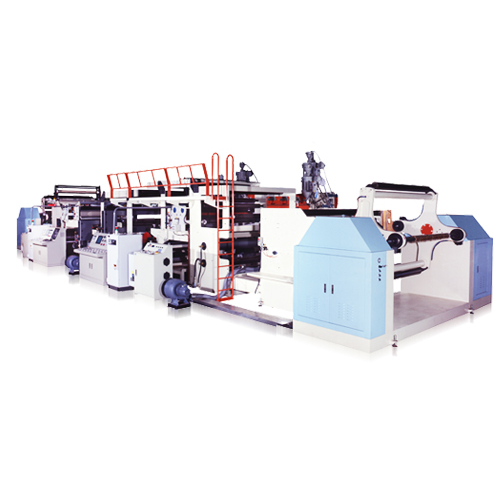

双面双层共挤压复合淋膜机

产品分类 : 淋膜机

主机压出量:350 Kgs x 2 Sets = 700 Kgs/Hour 副机压出量:150 Kgs x 2 Sets = 300 Kgs/Hour 线速:40-220 Meters/Minute 淋膜宽度:600MM~1600MM

三层共挤FFS重包装吹膜机

产品分类 : 吹膜挤出机

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

大型农业、地膜及工业用吹膜机

产品分类 : 吹膜挤出机

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr

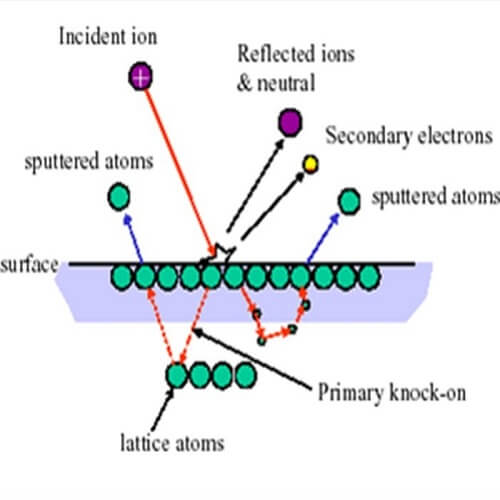

EMI SHIELDING

Protect parts from electromagnetic interference. It is used to protect electrical signals from the outside world. Currently, construction methods for anti-EMI are electric plating, sputtering, spraying, electric paint, or the direct use of the shielding effect of metal materials, such as the use of stainless steel, aluminum, iron or aluminum-magnesium alloy, and other materials. The metal piece of masking is low cost and meets current environmental regulations. But the processing and assembly are complex and miscellaneous and are poor stability. Water electroplating, electric plating, conductive paint, and other environmental laws and regulations conflict or doubt, the establishment of the new plating plant is not easy in the future and will gradually be phased out and replaced. So far, workers using a vacuum sputtering process and the magnesium alloy should be the main way to effectively combat EMI.

EPE 发泡管、套角押出机系列

产品分类 : 发泡挤出机

SP6 Series

产品分类 : 马达

Stack Type Flexographic Printing Press

产品分类 : 柔版印刷机

他的RPM系列柔性印刷机将性能和经济价值结合在一起,为我们的客户提供服务。感谢我们的人机工程学,用户友好的冲压设计,使机器操作变得简单而简单。工作变动不再是一项繁重的任务,减少了停机时间,并增加了利润。

SINGLE-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-1S 20-50)

产品分类 : 分切机和复卷机

SRB-A-1S, one shaft type semi-automatic rewinding machine. It's a strongly stable machine for rewind aluminum foil & cling film. Which is friendly, easy-operate for a novice. SRB-A-1S is compatible for cling film and catering aluminum foil. It can solve the temporary requirement when you need to exchange materials. The mother roll available width is from 200-500 mm. The max rewinding speed is up to 500M/min. The finished product can be 1000M the longest. Machine uses electric speed adjustments. You can control the rewinding time more precisely, arrange manpower more effectively. SRB-A-1S multiple functions rewinding machine brings you better operation and higher efficacy. Welcome to consult machine with us. We will at your service.

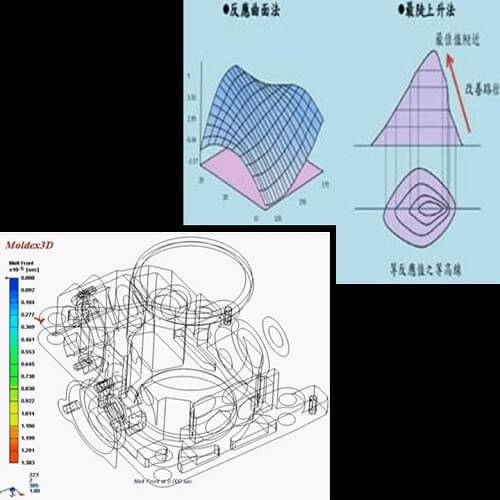

PROCESS OPTIMIZATION

产品分类 : 注塑模具

In-Mold Decoration (IMD) is an efficient, durable and cost effective technique for printing, painting, and forming plastic decorations. However, a large number of parameters involved IMD manufacturing processes and the complex relationship between these parameters make the determination of the optimal parameter setting a challenging task. This paper proposes a systematic framework integrating Response Surface Methodology (RSM) and logistic regression to improve the yield of IMD manufacturing process. The integrated framework becomes easy to identify the optimal parameter setting,saving a great deal of time and money in the manufacturing process. On the empirical study in collaboration with Yomura, the proposed framework shows the significant result from 10% to 87.5% validating the viability of the proposed framework in real setting. (Key words: IMD, In-Mold Decoration, Parameter Optimization, RSM, Response Surface Methodology, Logistic Regression) EXPERT ANALYTICAL SYSTEM Yomura Technologies employs state-of-the-art technologies to select materials, validate component designs, develop tool designs and optimize its processes, ensuring that innovative concepts are achievable at the lowest cost of production. (Keywords: Moldex3D, Moldflow, PowerMill Pro, CAD system)