- The integrated innovative wise technology with reliable Distributed Control System contains higher performance. Software combined with State-of-art window screen to provide smart and instinct object-oriented editing style hybrid switching with simple and popular PLC ladder program editor. His high-speed Ethernet communication network link-up between Humanity Interface and remote devices to displaying the future one-stop control advantages!

- It can be broadly applied to automated machinery control, such as injection molding extruder machine controllers and equipment

ARICO - The Best Solution Of AR Series - Controller

ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision AR Series - Controller and related application equipment, but also provides high-quality AR Series - Controller with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with AR Series - Controller, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.

-

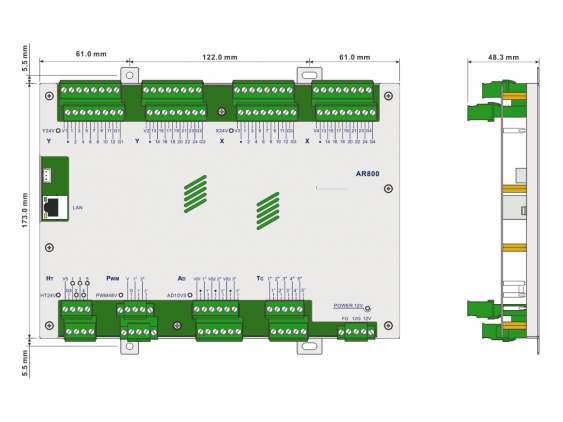

Dimension: 184 × 244 × 48.3mm

- It is simple to update all of program via USB memory driver

- DCS control (HMI and Remote I/O module) for easy access of external device and/or controller

- Various HMI size options: 5.6", 7", 8", 10.4" and 12.1" or touch panel(10.4" & 12.1")

- High speed Ethernet communication between HMI and Remote I/O module

- RS485 and Ethernet(Option) Interface

- State-of-the-art window system HMI Screen Editor design by ARICO

- PLC ladder editor for process program

- It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high

- I/O function define self and shift function

- Flip up icon of screen and alarm message

- PLC Real-Time control

- The 10 levels control for user

- The present screen picture can be saved via USB port to external memory device (USB memory device)

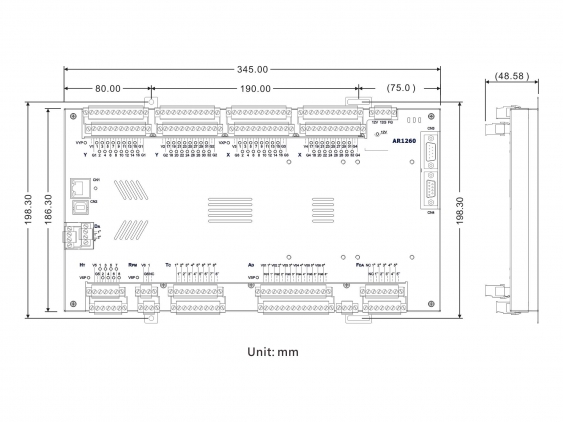

- Dimension: 198.3 × 345 × 48.58mm

- Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more than 2 times the displacement

- It is simple to update all of program via USB memory driver

- DCS control (HMI and Remote I/O module) for easy access of external device and/or controller

- Various HMI size options: 5.6", 7", 8", 10.4" and 12.1" or touch panel(10.4" & 12.1")

- High speed Ethernet communication between HMI and Remote I/O module

- RS485 and Ethernet(Option) Interface

- State-of-the-art window system HMI Screen Editor design by ARICO

- PLC ladder editor for process program

- The Demolished architecture, CPU board can be upgraded to more powerful new one on base main control board

- It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high

- I/O function define self and shift function

- Flip up icon of screen and alarm message

- PLC Real-Time control

- The 10 levels control for user

- The present screen picture can be saved via USB port to external memory device (USB memory device)

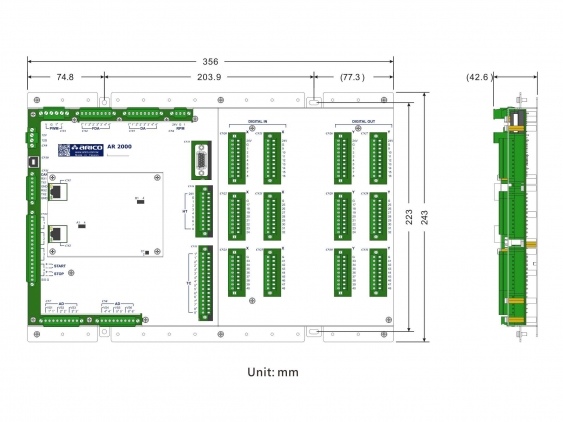

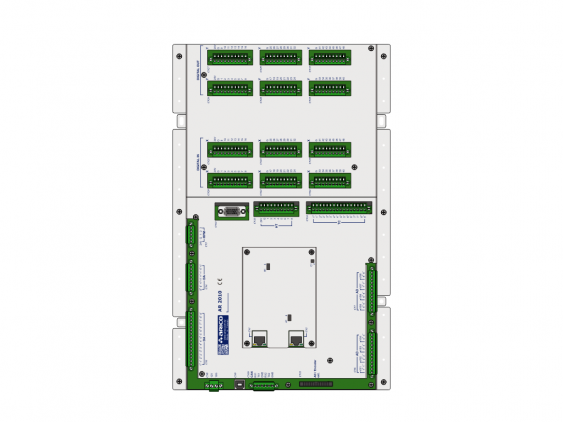

- Dimension: 243 × 356 × 42.6mm

- Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more than 2 times the displacement

- It is simple to update all of program via USB memory driver

- DCS control (HMI and Remote I/O module) for easy access of external device and/or controller

- Various HMI size options: 5.6", 7", 8", 10.4" and 12.1" or touch panel(10.4" & 12.1")

- High speed Ethernet communication between HMI and Remote I/O module

- RS485 and Ethernet(Option) Interface

- State-of-the-art window system HMI Screen Editor design by ARICO

- PLC ladder editor for process program

- The Demolished architecture, CPU board can be upgraded to more powerful new one on base main control board

- It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high

- I/O function define self and shift function

- Flip up icon of screen and alarm message

- PLC Real-Time control

- The 10 levels control for user

- The present screen picture can be saved via USB port to external memory device (USB memory device)

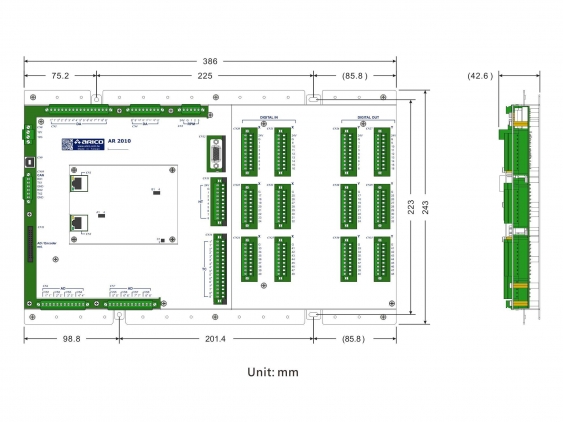

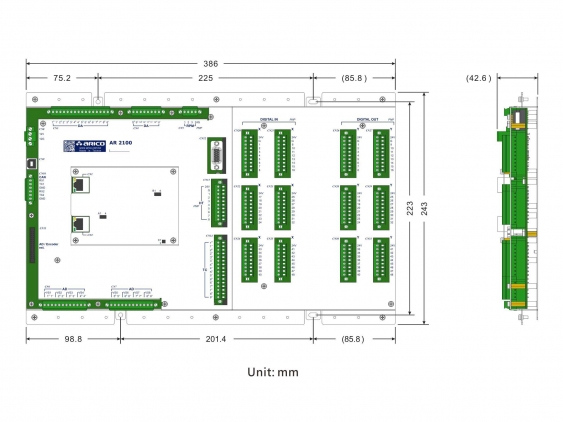

- Dimension: 243 × 386 × 42.6mm

- Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more than 2 times the displacement

- It is simple to update all of program via USB memory driver

- DCS control (HMI and Remote I/O module) for easy access of external device and/or controller

- Various HMI size options: 5.6", 7", 8", 10.4" and 12.1" or touch panel(10.4" & 12.1")

- High speed Ethernet communication between HMI and Remote I/O module

- RS485 and Ethernet(Option) Interface

- State-of-the-art window system HMI Screen Editor design by ARICO

- PLC ladder editor for process program

- The Demolished architecture, CPU board can be upgraded to more powerful new one on base main control board

- It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high

- I/O function define self and shift function

- Flip up icon of screen and alarm message

- PLC Real-Time control

- The 10 levels control for user

- The present screen picture can be saved via USB port to external memory device (USB memory device)

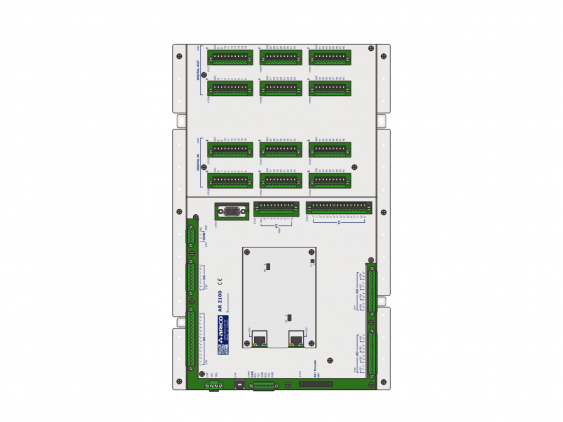

- Dimension: 243 × 386 × 42.6mm

- Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more than 2 times the displacement

- It is simple to update all of program via USB memory driver

- DCS control (HMI and Remote I/O module) for easy access of external device and/or controller

- Various HMI size options: 5.6", 7", 8", 10.4" and 12.1" or touch panel(10.4" & 12.1")

- High speed Ethernet communication between HMI and Remote I/O module

- RS485 and Ethernet(Option) Interface

- State-of-the-art window system HMI Screen Editor design by ARICO

- PLC ladder editor for process program

- The Demolished architecture, CPU board can be upgraded to more powerful new one on base main control board

- It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high

- I/O function define self and shift function

- Flip up icon of screen and alarm message

- PLC Real-Time control

- The 10 levels control for user

- The present screen picture can be saved via USB port to external memory device (USB memory device)

| Controller | AR800 | AR1260 | AR2000 | AR2010 | AR2100 |

| PLC CPU | 528MHz | 266MHz | 520MHz | ||

| Control CPU | 72MHz | 266MHz | 520MHz | ||

| Time base = 0.25ms | Time base = 0.25ms | ||||

| 1. Higher control precision | |||||

| 2. Software can be updated through USB | |||||

| IO Connection | NPN | NPN | NPN | NPN | PNP |

| Temperature PID Control | 5 | 8 | |||

| D/I Digital Input | 24(include 1PRM) | 32 | 32 / 48 | ||

| D/O Digital Output | 24 | 32 | 32 / 48 | ||

| A/D Analog Input | 16 bit * 3 | 14 bit * 6 | 16 bit * 6 | 16 bit * 8 | |

| Start/Stop Input | X | X | 0 / 4 | X | |

| FDA Analog Output | X | 12 bit * 5(0~+10v) | 12 bit * 4(0~+10v) | X | |

| D/A Analog Output | X | 12 bit * 0/2(0~+10v) | 12 bit * 0/4(0~+10v) | 12 bit * 8/12(0~+10v) | |

| PWM Output | 2 | X | 1 | X | X |

| RPM Count | 0 | 1 | 3 | ||

| FPGA | X | PLC CPU & Control CPU data transmitted through a parallel FPGA connection; allows more precise control accuracy | |||

| Controller | AR800 | AR1260 | AR2000 | AR2010 | AR2100 |

| Temperature Module | Man-machine communication allows 15 sets of temperature module expansions; | ||||

| each module includes 8-stage temperature control | |||||

| IO Expansion Module | X | Able to expand 1 module; each module | Able to expand 12 modules; each module | ||

| DI/DO*8(Max=8) | DI / DO * 16 (Max=192) | ||||

| A/D Expansion Module | X | X | 16 bit*8 | ||

| Encoder Expansion Module | X | X | 32 bit*4 | ||