| 型号 |

FS-40 OSSO |

FS-45 OSSO |

FS-55 OSSO |

FS-65 OSSO |

| 样式 |

单模头/ 单模架 |

| 使用塑料 |

PE/PP |

PE/PP |

PE/PP |

PE/PP |

| 螺杆直径(m/m) |

40 |

45 |

55 |

65 |

| 螺杆比例(L/D) |

24/1 |

24/1 |

24/1 |

24/1 |

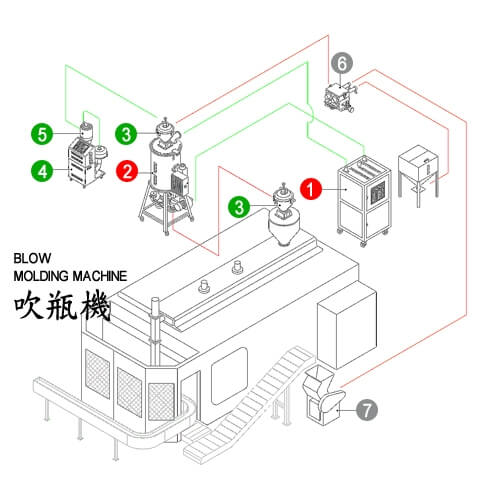

<● 移模方式採用導桿搭配油壓系統作動,採V型斜移作動方式。>

● PLC系统搭配独立式电控箱。

● 可加装选配自动广口切割机、成品输送带、和厚薄控制器。

● 高效能之螺杆设计,适合生产各种不同的塑料。

● 装配鍑鑫设计之移模刹车系统,移模稳定,定位精确。

| |

螺杆直径(M/M) |

机械类别 |

模头 |

模架 |

产品型式 |

| FS- |

40 |

(H) 平移式开关模采用线性滑杆 |

(S) 单模头 |

(S) 单模架 |

(O) 一般 |

| 45 |

(P) 平行式移模 |

(D) 双模头 |

(D) 双模架 |

(C) 双色 |

| 55 |

(O) 标准型/ 斜移式 |

(T) 三模头 |

|

(D) 双层 |

| 65 |

(A) 空压式 |

(F) 四模头 |

|

(T) 三层 |

| 75 |

(L) 前向取出机型 |

(E) 八模头 |

|

(F) 四层 |

| 80 |

(I) 侧向取出机型 |

|

|

(L) 六层 |

| 90 |

|

|

|

(V) 视窗 |

| 100 |

|

|

|

(P) PC奶瓶 |

| 范例 |

| FS- |

65 |

P |

D |

S |

D |