分类: 全自动押出中空吹气成型机

| 型号 | FS-120LSSO |

| 使用塑料 | PE |

| 产品容量 | 100-250 |

| 产品直径 | 260-650 |

| 螺杆直径 | 120 |

| 螺杆比例 | 28/1 |

| 押出量 | 270 |

| 储料量 | 26 |

| 螺杆驱动变频马达 | 100 |

| 螺杆驱动油压马达 | 4500 |

| 螺杆转速 | 20-65 |

| 油压驱动变频马达 | 75 |

| 油压驱动油压马达 | 125 |

| 原薄控制动力 | 10 |

| 空气压缩机(选购用) | 30 |

| 空气压力 | 6-8 |

| 锁模压力 | 162 |

| 油箱容量 | 210 |

| 加热点数 | 10 |

| 加热电量 | 45 |

| 总电力 | 176 |

| 模嘴外径 | 650 |

| 开闭模极限 | 500-2300 |

| 容模长度 | 1500 |

| 容模宽度 | 1300 |

| 机械水消耗量 | 1500 |

| 模具水消耗量 | 450 L/min |

| 246500 kcal/hr | |

| 机器净重 | 32 |

| 机器尺寸<L*W*H> | 5.7*9.6*6 |

● 操控面板结合触控式萤幕功能及分离式电控箱,便利操作。

● 此机型可加装多点式厚薄控制器。

● 螺杆及输料管以特殊钢材加工并且经氮化处理。

● 入料口采冷却水装置,控制温度。

● 吹气针部份具有水冷却装置。

● 创新机械手臂设计,可自动取出成品。

● 完善的安全防护装置,提供作业员安全、舒适的工作环境。

● 高效能油压回路系统,双向油压缸加强锁模力。

| EXPOSITION OF FULL SHINE'S MACHINE MODEL | |||||

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| Model | FS-75LSSO | FS-80LSSO | FS-90LSSO | FS-100LSSO | FS-120LSSO | ||

|---|---|---|---|---|---|---|---|

| Material | PE | PE | PE | PE | PE | ||

| 1 | Product capacity | Liter | 1-10 | 10-30 | 30-50 | 50-100 | 100-250 |

| 2 | Diameter of Product | m/m | 80-260 | 120-350 | 150-400 | 180-580 | 260-650 |

| 3 | Screw diameter | m/m | 75 | 80 | 90 | 100 | 120 |

| 4 | Screw L/D ratio | L/D | 24/1 | 24/1 | 24/1 | 28/1 | 28/1 |

| 5 | Extruding capacity | Kg/hr | 100 | 120 | 140 | 210 | 270 |

| 6 | Accumulator | Kg | 2.5 | 2.5 | 5 | 7-12 | 26 |

| 7 | Screw Drive Inverter motor | HP | 30 | 40 | 50 | 60 | 100 |

| 8 | Screw Drive Hydraulic motor | C.C. | 1450 | 2000 | 2500 | 3000 | 4500 |

| 9 | Screw ration speed | r.p.m | 15-65 | 20-65 | 20-65 | 20-65 | 20-65 |

| 10 | Oil Hydraulic drive Inverter motor | HP | 25 | 30 | 30 | 40 | 75 |

| 11 | Oil Hydraulic drive Hydraulic motor | HP | 20 | 50 | 75 | 100 | 125 |

| 12 | Power of thickness control | HP | 5 | 5 | 7.5 | 10 | 10 |

| 13 | Air compressor(Optional) | HP | 7.5 | 15 | 15 | 20 | 30 |

| 14 | Pressure of air | kg/cm2 | 5-7 | 5-7 | 6-8 | 6-8 | 6-8 |

| 15 | Clamping force | ton | 28 | 42 | 50 | 100 | 162 |

| 16 | Oil tank capacity | Gallon | 80 | 100 | 140 | 200 | 210 |

| 17 | Number of heaters | Zone | 6 | 7 | 7 | 10 | 10 |

| 18 | Heating capacity | Kw | 26 | 28 | 32 | 36 | 45 |

| 19 | Total installed power | Kw | 68 | 81 | 92 | 111 | 176 |

| 20 | Extruding mouth outer diameter | m/m | 200 | 280 | 350 | 450 | 650 |

| 21 | Open close daylight | m/m | 200-700 | 230-930 | 340-1000 | 360-1200 | 500-2300 |

| 22 | Length of mold capacity | m/m | 680 | 775 | 850 | 1200 | 1500 |

| 23 | Width of mold capacity | m/m | 500 | 640 | 820 | 1000 | 1300 |

| 24 | Machine water consumption | L/hr | 900 | 900 | 1000 | 1200 | 1500 |

| 25 | Mold water consumption | L/min | 230 | 230 | 230 | 230 | 450 |

| kcal/hr | 31500 | 31500 | 46623 | 46623 | 246500 | ||

| 26 | Machine net weight | ton | 7.2 | 11 | 12 | 18 | 32 |

| 27 | Machine dimension<L*W*H> | m | 3.4*2.5*2.8 | 3.8*2.8*2.8 | 5*3*3.3 | 5.5*3.5*3.3 | 5.7*9.6*6 |

|

Outdoor product |

Float |

21L, 25L drum |

10L. 20L. 30L Jerry cans |

|

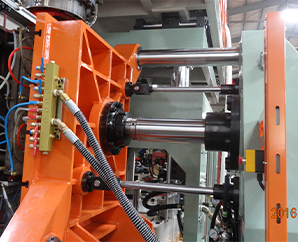

Close and open mold is controller by linear slide way, make in Germany |

Fans with Barrel screw set |

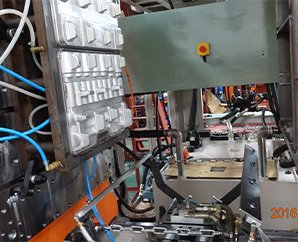

FS-100LSSO machine with robot arm |

FS-100LSSO Single Accumula |

|

Mold carriage is operated by double piston cylinder |

Parison enlarger is pneumatic-driven |

Separate control cabinet is equipped with Fuji 10.4” colorful HMI |

Separate PLC control cabinet |

|

Sub Cylinder speed up mold close, and Main Cylinder is driven with higher clamping force |

|

Watering cans |

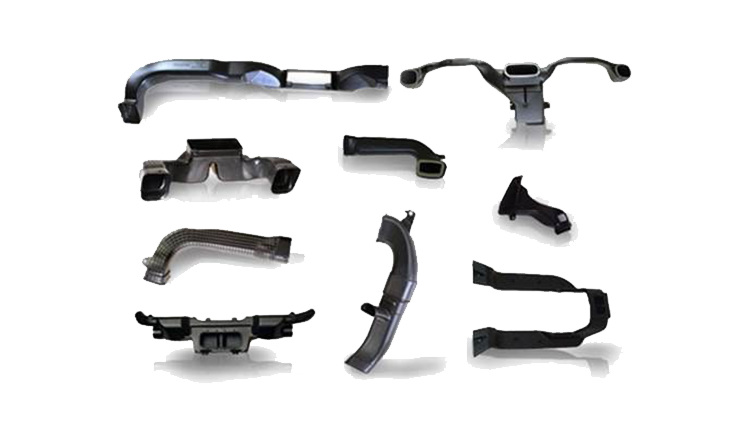

Automotive |

210L~250L Double L ring drum |

|

Gardening supplies |

Blow Molded Plastic Bucket |

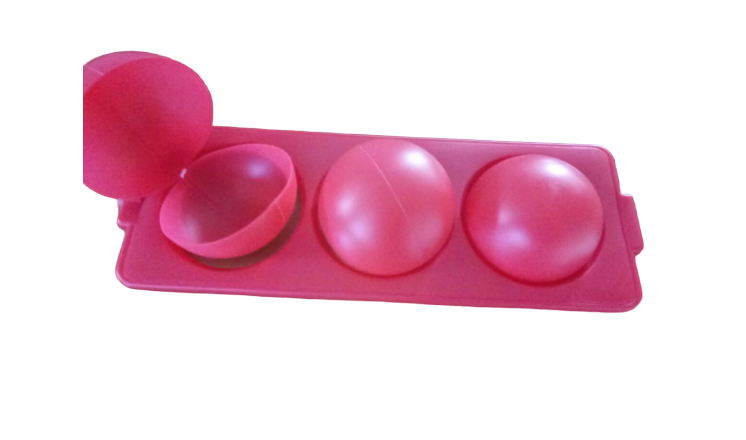

Seat cushion |

|

Outdoor supplies/Bird balls |

Water tank |

Jerry Can Making Machine |