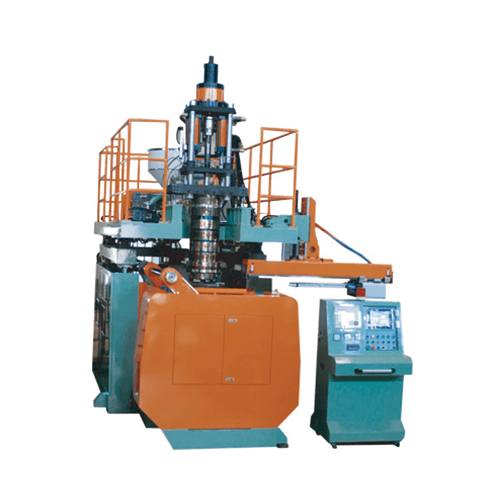

分类: 全自动押出中空吹气成型机

| 型号 | FS-90ISSO |

| 使用塑料 | PE |

| 产品容量 | 30-50 |

| 产品直径 | 150-400 |

| 螺杆直径 | 90 |

| 螺杆比例 | 24/1 |

| 押出量 | 140 |

| 储料量 | 5 |

| 螺杆驱动变频马达 | 50 |

| 螺杆驱动油压马达 | 2500 |

| 螺杆转速 | 20-65 |

| 油压驱动变频马达 | 30 |

| 油压驱动油压马达 | 60 |

| 厚薄控制动力 | 7.5 |

| 空气压缩机(选购用) | 15 |

| 空气压力 | 6-8 |

| 锁模压力 | 44 |

| 油箱容量 | 140 |

| 加热点数 | 7 |

| 加热电量 | 32 |

| 总电力 | 92 |

| 模嘴外径 | 350 |

| 开闭模极限 | 340-850 |

| 容模长度 | 850 |

| 容模宽度 | 750 |

| 机械消耗量 | 1000 |

| 模具水消耗量 | 230 L/min |

| 46623 kcal/hr | |

| 机器净重 | 12 |

| 机器尺寸<L*W*H> | 5*3*3.3 |

● 操控面板结合触控式萤幕功能及分离式电控箱,便利操作。

● 模板之开闭与料管平行,机身与模头可上下、前后移动,方便模具之装卸更换。

● 螺杆及输料管以特殊钢材加工并且经氮化处理。

● 此机型可加装多点式厚薄控制器。

● 入料口采冷却水装置,控制温度。

● 吹气针部份具有水冷却装置。

● 完善的安全防护装置,提供作业员安全、舒适的工作环境。可另外加购电眼装置于模架上,提供多一层的防护。

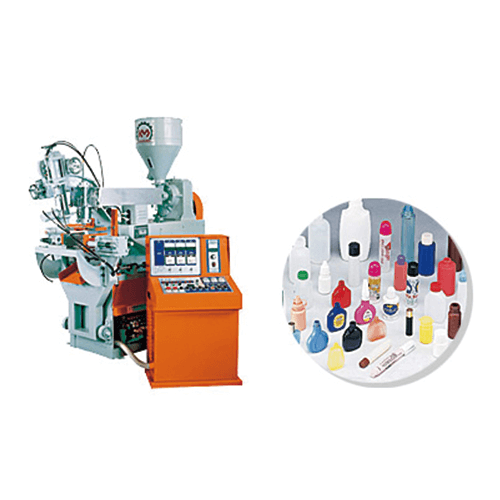

● I 系列机型,最适合吹塑异形及特殊塑胶产品。

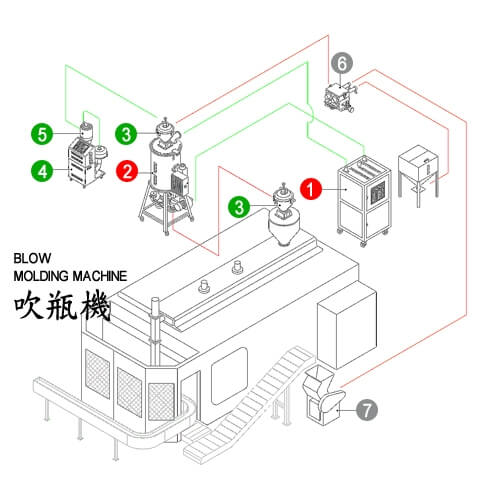

| EXPOSITION OF FULL SHINE'S MACHINE MODEL | |||||

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |