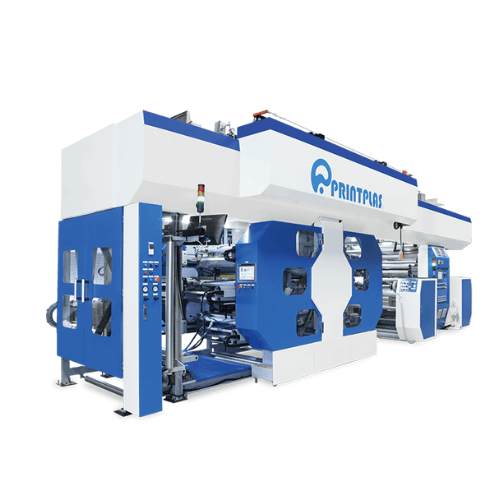

.本机装配网路连结电控系统,可远端诊断程式及电器装置

.中央大轮为双壁式内冷却循环设计,轮面经精密研磨,确保印材平顺贴附,印刷精准

. 80MM厚度车壁提供各印刷座稳定及无振动的基础

.伺服传动主机/导入/导出/收卷连动确保料卷张力恒定

.每色均有超微细印压微调装置,达到精细彩艺印刷要求

.长拱型干燥风箱搭配高效率风车及排风马达,确保高速印刷时油墨充分干燥

.下列可供选择加配:

a.含记忆组的伺服印压自动化

b.快速套筒式系统

c.自动接料装置

d.反转印刷装置

/规格:

| 型 号 | 印刷宽度 | 材料宽度 | 印刷长度 | 印刷速度 * |

| PKF600-6CI | 600MM | 650MM | 300~900MM | 50~200M/MIN |

| PKF800-6CI | 800MM | 850MM | 300~900MM | 50~200M/MIN |

| PKF1000-6CI | 1000MM | 1050MM | 300~900MM | 50~200M/MIN |

| PKF1200-6CI | 1200MM | 1250MM | 300~900MM | 50~200M/MIN |

| PKF1400-6CI | 1400MM | 1450MM | 300~900MM | 50~200M/MIN |

| PKF1600-6CI | 1600MM | 1650MM | 300~900MM | 50~200M/MIN |

* Printing speed varied depending on different printing condition. *印刷速度依印刷条件不同而异

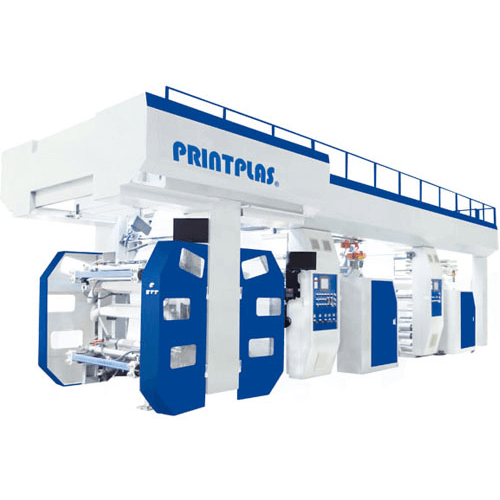

CI FLEXO PRINTING PROCESS

Flexographic printing presses utilize photopolymer printing plates that feature a reflective relief image of the desired print. The elevated portions of the plate receive ink through an anilox roller, which subsequently transfers it onto the substrate. The key steps involved in the printing process including:

- Ink Delivery System: The ink delivery system consists of the ink reservoir, pump, and pipes that transport ink to the anilox rolls. It ensures a steady supply of ink and maintains consistent ink flow throughout the printing process.

- Plate Cylinder: The plate cylinder holds the printing plates and rotates in sync with the anilox rolls. As the substrate passes through the press, the plate cylinder transfers the inked image onto the substrate.

- Print Unit: The print unit comprises the anilox rolls, doctor blades, printing plates, and impression cylinder. These components work together to apply the desired amount of ink onto the substrate and create high-quality prints.

- Web Tension Control: Web tension control systems ensure proper tension and alignment of the substrate throughout the printing process. They prevent issues like wrinkling, stretching, or misalignment, which can affect print quality.