TaipeiPLAS 2022 Live | PRM x KAOLU x PIDC

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 9/30(Fri.) 15:00 (GMT+8) 【KaoLu Enterprise】 Kao Lu Enterprises Co. Ltd., established in 1980, has been dedicated to manufacturing and supplying premium quality pneumatic components such as valves, cylinders, and ancillary accessories. 【Plastics Industry Development Center | PIDC】 What's the key role that PIDC plays in Taiwan society and how they provide services to plastics manufacturers. By interviewing General Manager of Dr. Hsiao, he would share the insight of SDGs, 2050 Net Zero programme, and also provide advice to Taiwanese enterprises.

Multi-layers Die Head Manufacturer at K 2022 | HSIN LONG

Hsin Long Thread Rolling Machine Co., Ltd. is knowing for high-quality products, such as blown film machine, extrusion die and extruder filter, and their post-sale service. By interviewing Ms. Sandy Chen, Production Manager, we gained the information about how Hsin Long apply digitalization in their equipment.

TaipeiPLAS 2022 Live | PRM

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 10/1(Sat.) 15:00 (GMT+8) 【PRM exhibition insight interview】 We'll introduce the innovative machinery and techniques by interviewing exhibitors at TaipeiPlas 2022. To those who cannot attend the exhibition and overseas buyers, you can watch our on-site interviewing video to obtain the latest information.

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023! Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

Quick Mold Change - Clamping System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Current Situation in Indian Extrusion Market | CCM India Interview

At the end of 2020, we had an online interview with Mr. Prashant Tanna from CCM India(Chichang Machinery India). At the interview, we have discussed various topics related to the plastics and rubber industry. Mr. Tanna sincerely replied to our questions and shared a deep insight especially about the plastics extrusion machinery market in India. We are grateful for the insight that we gathered from Mr. Tanna about the current situation of the Indian market, travel restrictions, benefits of having an agent in the local market, and so on. Let's watch the interview video together and leave your comment at the comment section!

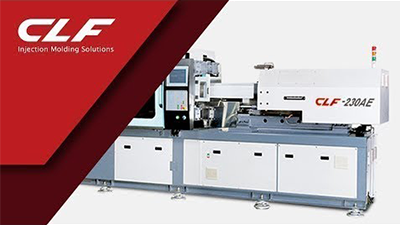

All Electric Molding Machine | CLF

All Electric Injection Molding Machine Features: ⚫Electricity Regeneration Circuit Electricity Saved by 15% ⚫Employs German Siemens control and servo motors for excellent performance and high accuracy. ⚫High performance injection unit that enhances the exceptional features of servo control.High speed,stability and accuracy are guaranteed. ⚫In-house software development capability combined with technical support from Siemens. ⚫Standardized hardware design simplifies the maintenance works and reduces the spare parts stock. ⚫Simultaneous control on multi-axes shortens molding cycle time dramatically. ⚫Overall super rigid structure minimizes running vibration. ⚫Exclusive energy-regeneration function not only provides electricity-saving and environmental protection, but also meets today's trend of energy-saving. ⚫Ergonomics operation interface. ⚫The access level to controller management can be ranked. ⚫Rigid platen design exhibits superior parallelism. ⚫Supports remote monitoring functions.

IoT Injection Molding - Hot Runner Temperature Controller-TC50 | ARICO

【AUXILIARY EQUIPMENT IN THE VIDEO】 Hot Runner Temperature Controller-TC50 for Injection Molding Machines, IoT Solutions from ARICO. 【FEATURES】 HMI: 7" LCD display with touch panel Group setup function Mold Memory Power balance detection and display Synchronous heat up and cool down Self-diagnosis log Mold leakage detecting Injection machine connect for I/O function VNC function(option) 【SPECIFICATIONS】 Thermocouple type: J/K Temperature unit: ℃/℉ Heating mode selectable The maximum drive current is 15 ampere for each zone Temperature PID control Zero cross/Phase angle output trigger modes Auto detect the frequency of power source The current detect and display The output with auto/manual setting The soft-start for dehumidification Boost Standby Output mode: Stop/Manual/Slave/continually selectable when Thermo-coupler broken Overload protection for electric Overload protect for heating output The protect mode of power source when wrong input Auto shutdown when abnormal work on the module The fast fuse used to protect TRIAC 【ABOUT ARICO】 ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. Founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. ARICO is not only good at producing customized precision Hot Runner Temperature Controllers and related application equipment but also provides high-quality Hot Runner Temperature Controllers with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia, and other countries.

2024 NPE Orlando Interview | ISI

I had the pleasure of meeting Mr. Joe Whann at NPE Orlando. Joe is not only brilliant but also incredibly friendly! He provided an insightful introduction to the wide range of services offered by ISI and shared how they have become a leading agent in the USA. Don't miss out on learning about their impressive journey and expertise!

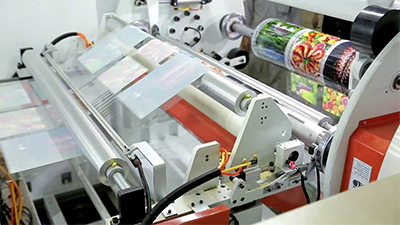

High Speed ELS Rotogravure Printing Machine | WORLDLY

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY Machine Specifications - Max machine speed: 350 m/min - Web width: 1000 / 1200 / 1300 mm - Printing cylinder circumference: 350 - 900 mm - Material diameter: 800 / 1000 mm - No. Color: 10 colors

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.