回收机械及设备

热门讯息

BoReTech: PCR Plastic Recycling Process From BoReTech

PCR (Post-Consumer Recycled) plastics are made from plastic waste that has been collected from consumer products and recycled. These plastics are mainly derived from PET bottles, HDPE bottles, and LDPE films. For food-grade waste plastic recycling, PET bottle recycling is a major development trend in the waste plastic recycling industry. The process of recycling and washing PCR plastics involves several steps, including washing, grinding, pelletizing, and SSP (Solid State Polymerization) to produce food-grade recycled flakes and pellets that meet FDA or EFSA certification.

Benefits of Recycling Plastic Film and Bag Production Wastes In-house

Due to the large size of productions of 15 years old fast-growing bag manufacturer for many different companies, the scraps generated from plastic flexible packages, patch and soft handle bags, punched-out handle bags, courier bags, exam bags, gift packages, shrink films and document pouches were considered as high. The bag producer needed to work with several professional recyclers to reprocess them.

FIMIC: Filtration Technology for PET Recycling

Polyethylene Terephthalate or simply PET, is one of the most recyclable plastics, widely used world-wide in many different applications. Light, strong, durable and safe, PET offers a number of advantages being almost uniquely among plastics. Because of PET's incredible performance and recyclability it is one of the most sustainable packaging materials. It is in fact approved as safe for use in direct food contact all over EU, as well as many other Countries, both in virgin or recycled form.

GENIUS: Empowering the Blown Film Industry with Sustainable Solutions at Expo Plasticos 2023

Genius Machinery, a leading manufacturer of recycling machinery, will be participating in Expo Plasticos 2023 in March. Our aim is to display the newest innovations in the plastic recycling industry to all attendees. An essential product we will be featuring at the expo is the air cooling pelletizing machine.

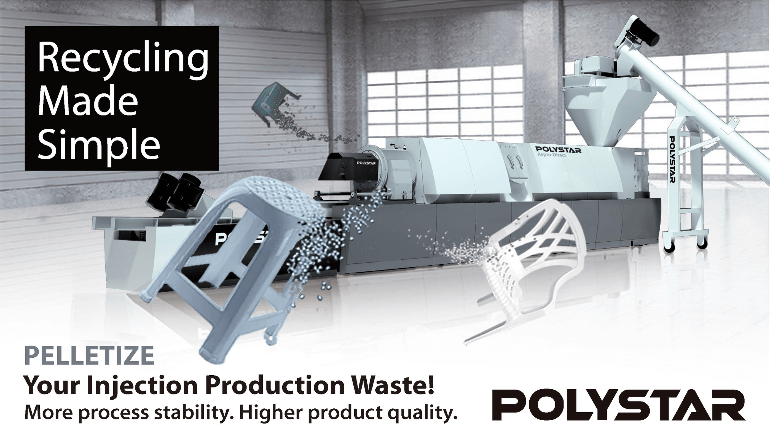

Why to Use Recycled Plastic Pellets for Injection Molding instead of Regrinds?

Using recycled plastic pellets for injection molding brings several benefits to businesses as well as to the environment. These can be listed as reducing waste, conserving resources, saving material costs, improving sustainability, and creating positive public relations. Recycling injection molding manufacturing wastes is one of the fastest ways of generating recycled plastic for injection molding. On the other hand, using recycled plastics in injection molding in pellets form is also found superior to regrind form by many injection molding manufacturers.

How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, and, most importantly, invest in a reliable plastic recycling machine.

BoReTech: How to Make Recycling Waste PET Bottles Easier and Produce High-Quality rPET?

The global brands announced they would give up using virgin plastics in their products, which means more recycled plastics and rPET is required in markets. More than 60 brands and retailers have set corresponding reduction targets on the use of virgin plastic. The new commitment proposes that by 2025, the absolute benefit of virgin plastic will be reduced by nearly 20% compared with 2018.

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.