注塑模具

注塑模具是塑料制品生产中的关键工艺工具,通过将熔融塑料注入模腔进行冷却成型,实现批量化、结构精准和外观统一的塑料部件制造,广泛应用于家电、3C电子、日用品、瓶胚包装、汽车零部件和行李配件等领域。

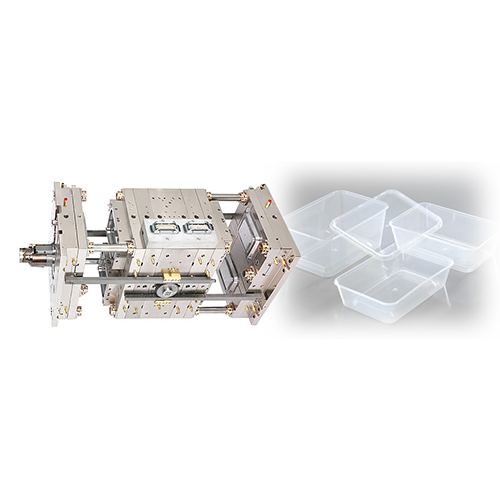

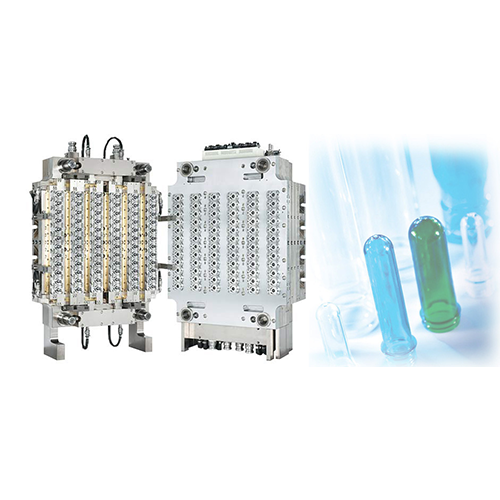

PRM-Taiwan 提供多种注塑模具技术,包括: 双色/多色注塑模具(适用于多材料或多颜色产品), IML模具(模内贴标一体化成型), 行李配件模具(如拉杆、把手类产品), 瓶坯模具(用于瓶装包装制程), 以及堆叠模具(Stack Molds)(适合高产能、多腔成型场景)。

DESIGN AND DEVELOPMENT PARTNER

产品分类 : 注塑模具

JDM / ODM SERVICES When bringing a new product to market or re-launching an existing product with new features, key success metrics are quality and timing t o market. Either or both may be negat...

CONTRACT MOLD MANUFACTURE

产品分类 : 注塑模具

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market ...

DOUBLE INJECTION MOLDING

产品分类 : 双射和多射注塑模具

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a...

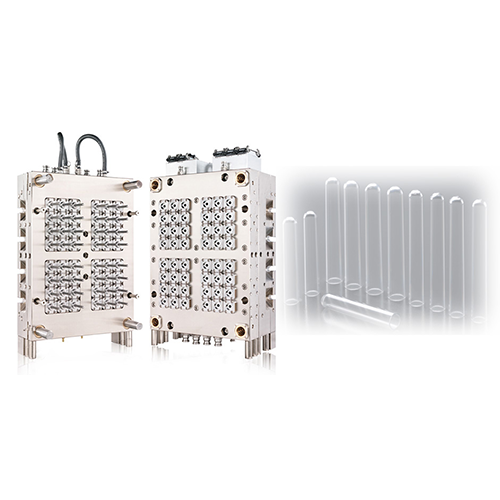

SINGLE INJECTION MOLD

产品分类 : 单射注塑模具

Single Injection Molding is a standard process that YOMURA TECHNOLOGIES excels at. Our YangMei plant is equipped with a resin feeder system to increase yield rates for mass volume production. Ma...

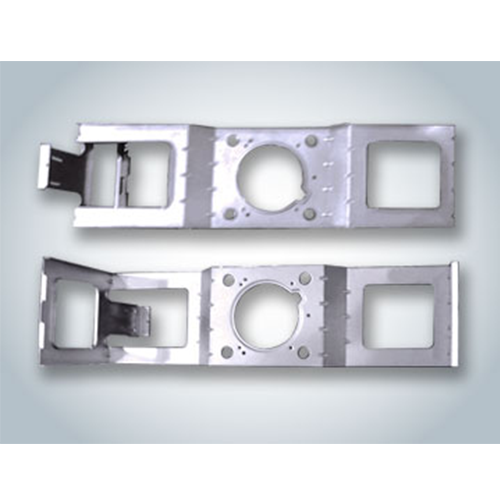

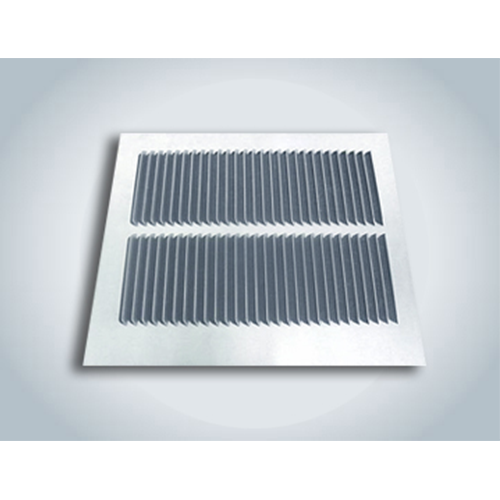

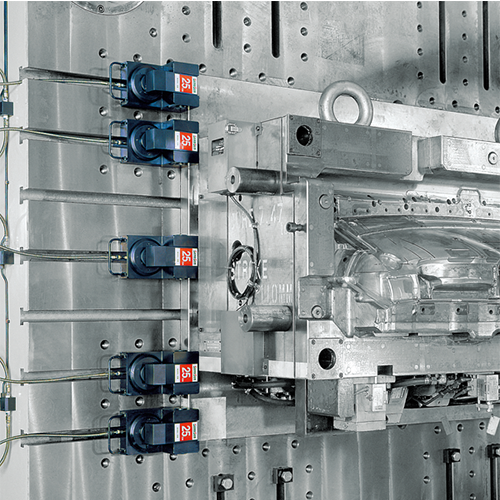

射出机、压铸机快速换模系统

产品分类 : 注塑模具

It is an era for making high frequency mold change with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to...