WORLD STEEL: Build Your Flexible Production Line

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, we have the best engineering crew in the industry to provide total solutions which include design, customization and development. To meet customer needs, we are committed to developing new models and increasing product competitiveness.

Plastic Drums and Plastic Drum Machines: A Quick Guide

Blue HDPE plastic drums are very common containers in warehouses and transport facilities across the world. These sturdy and durable containers are not only cost-effective but also incredibly useful when it comes to the safe and secure storage and transport of many different industrial goods. Given their popularity, plastic drum-making machines are also in constant demand by customers who seek effective solutions for their industrial businesses.

MOLDPOWER is Looking for Hot Runner System Distributors Worldwide

In 1997, Mr. Chen, Chung-Le and Mr. Chen, Ya-Mo co-founded Mold Power Co. Our core-values are honesty, quality, expertise, and a better future together. We are devoted to the design and the manufacturing of hot runner systems and originated the brand “Mold Power”. Because of our superior product performance, our products have been adopted by quite a few domestic mold plants for appliances, food containers, cosmetics, automotive parts, medical supplies, electronic products etc.. We provide customers with complete products and technology sharing.

Full Shine Machinery's Expertise in PC Water Bottles Making Machine

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.

Discovering Latest TungYu Solutions at 2024 Rubber and Plastics Exhibition

As part of its corporate development strategy, we will participate in the Global Rubber and Plastics Exhibition in 2024. This international exhibition brings together top companies and experts from the global rubber and plastics industries. Participation in this exhibition will provide TungYu with a platform to showcase its latest technology and products, engage in exchanges and collaborations with peers from around the world, and further enhance the company's international influence.

40th Techmation: Digital Low Carbon Dual Wheel Drive, Intelligent Manufacturing in the Future

2024 marks the 40th anniversary of Techmation. Over the past 40 years, Techmation has taken the first Chinese screen injection molding machine controller in Asia as the starting point, vertically breaking through technological barriers, horizontally expanding product applications, and steadily drawing an industrial application map with Techmation control system as the core.

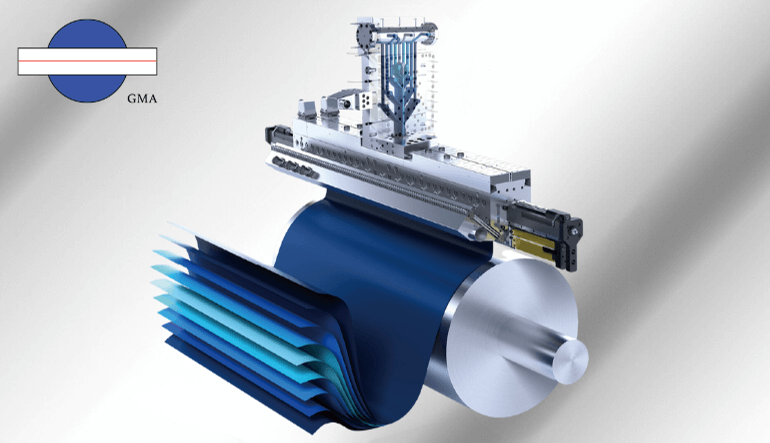

GMA Machinery's Evolution from Extrusion die Craftsmanship to Slot Die and Coating Equipment - A Journey of Unwavering Excellence

For over 30 years, GMA Machinery, with its rich experience in extrusion die design and manufacturing, has caught the attention of global extrusion machine market. What prompted GMA Machinery to smooth transition from specialized extrusion die design and manufacturing to enter the slot die and coating equipment and equipment sector? How did it swiftly emerge as the new choice for slot die and coating equipment in the optoelectronics and precision manufacturing industries?

TOP 6 BLOW MOLDING EXAMPLES BY EXTRUSION BLOW MOLDING MACHINES

There are lots of Extrusion Blow Molding(Moulding) Products in our daily life. Blow molding is a manufacturing process for forming and joining together hollow plastic parts. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding (one stage), and injection stretch blow molding (two stages). In the extrusion blow molding process (EBM), plastic is melted and extruded into a hollow tube (a plastic parison). This plastic parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected. It is designed to manufacture high volume hollow plastic products.

TungYu's Pathway To Net-Zero Emissions In 2050

TungYu is actively undertaking a comprehensive carbon footprint reduction plan to meet the challenges of achieving net-zero emissions by 2050. The initiative targets greenhouse gas inventory, product carbon footprint, and low-carbon and energy-efficient design throughout the product lifecycle, implementing a range of specific measures to achieve sustainable development goals.

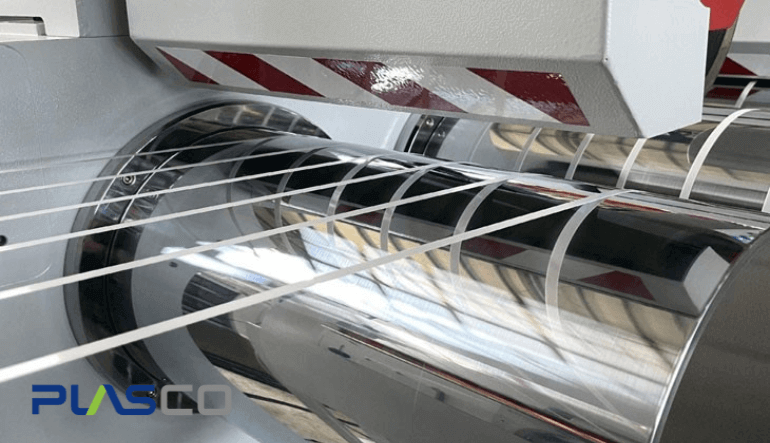

PLASCO: The Essential Reference of Strapping Band Extrusion Machines

Within the packaging industry, PP/PET strapping band making machines stand as vital equipment. These machines are employed in the production of strapping bands, which serve to secure a diverse range of goods, such as boxes, pallets, and drums. The utilization of PP/PET strapping band extrusion machines yields enhancements in packaging efficiency, cost reduction, and safety improvements. Our discussion will encompass the components, varied strapping band grades, their applications, as well as a comprehensive buying guide for PP/PET strapping band extrusion lines.

CHEN WAY : How to Select the Correct Blow Molding Material for Your Products

Extrusion blow molding machines can produce a wide variety of hollow plastic products. It is important to keep in mind that in order to produce exceptional products, besides purchasing high-quality Blow Molding Machines, it is also crucial to choose the correct blow molding material for each project. This ensures that the end products will have the desired properties and will also be able to withstand the environment(s) that they will be exposed to.

Here are 10 key points to understand extrusion dies.

This article explores extrusion dies, a vital component in the plastics industry. It focuses on "flat extrusion dies," which create uniform sheets and films by guiding polymer material through a chamber. The die's structure includes a body, width, and thickness adjustment systems. Extrusion dies find applications in various industries, from stationery boards to automotive films. The manufacturing process involves precise machining and finishing.