回收机械及设备

热门讯息

Start Your CPP Film Recycling Right Away with POLYSTAR

Cast polypropylene, also known as CPP, is well known for its versatility. CPP is gaining popularity as a more appealing packaging material than polyethylene in many areas because it has higher clarity and better heat resistance. The qualities of the CPP film can be customized to fit specific packaging, performance, and processing needs...

PP Tray Washing Line for High-Value Application by BoReTech Achieves Efficient Performance

Nextek said that the UK consumes 210,000 tons of food-grade PP per year. In comparison, China generates an average of about 1.5 million tons of plastic tray waste annually. There are 250,000 tons of waste disposable lunch boxes to be recycled, accounting for only 1% of all plastic waste that is recycled.

POLYSTAR: How to Use Recycled Pellets in the Production Process - Post-consumer Waste

Plastic pellets are small granulates, used in Blown Film Machines, Injection Machines, Molding Machines, and other machines that produce plastic films, bottles, containers, bags, and more. These small pieces of material are the most important...

POLYSTAR: What is the Difference Between Post-industrial Recycling and Post-consumer Recycling?

When it comes to plastic recycling, there are a few things you should know before deciding on the right machines. There are two types of plastic recycling in general, Post-industrial recycling and Post-consumer recycling. In this article, I will explain the difference between recycling these two types of plastic waste...

POLYSTAR: Recycled Plastic Pellets from PP Raffia and Woven Production – Tips to Reuse them Better

Which recycled plastic pellets should go back to PP tape extrusion line? On average, a 5-10% production waste is generated during the PP woven bag making process at different stages of the production: extruder start-up lumps, waste due to blockage in extruder die head, tape winding, circular loom (weaving defects), coating/lamination stage, pp woven/FIBC bag conversion and printing.

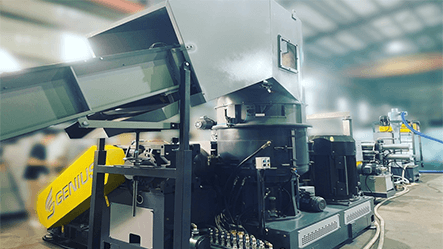

Recycling- Bigger Pelletizing Extruders in High Demand

With the growing importance of recycled-based products for both rigid and flexible packaging, the demand for plastic recycling continues to increase worldwide. Recyclers are now buying multiple machines at the same time and more notably, larger-capacity machines.

GENIUS: Constantly Adjusting to Different Recycling Policies Around the World

Genius Machinery has already served a lot of recyclers around the world, even in the pandemic period. They keep the principal motivation in their mind: increasing productivity creates more benefits and infinitive possibilities in the industrial area. Connect with Genius Machinery, to let them back you up. Smart Recycling, the Genius Way.

POLYSTAR: Does your Factory have the Right Solution for Recycling your Materials?

Producers understand the relevance of recycling the plastic waste created by their facilities. The shortage of resins drove plastic producers to respond faster and take action to recycle their factory waste, and thus to explore innovative ways to recycle post-consumer waste.