FCS: The Trend and Choice of Plastic Houseware and Toy Injection Molding

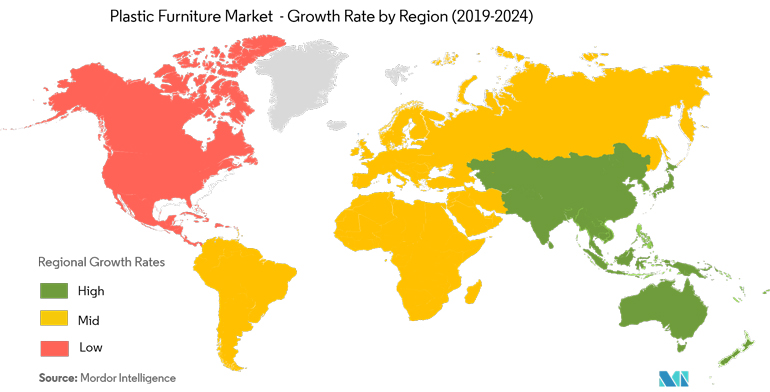

The global plastic furniture market size was valued at USD 11.9 billion in 2018 and is expected to expand at a CAGR of 3.9% from 2019 to 2025. The Global Toys and Games market is forecasted grow at a CAGR of 4.5% during 2019 - 2024. FCS servo energy-saving injection molding machines have been producing steadily for the famous houseware and toy manufacturers in Taiwan, India and Latin America, also helping them keep the leading position in the markets.

The trend of plastic products are closely related to end-users demand. The increasing demand for low-cost, lightweight, and durable purpose is driving end-users to adopt plastic furniture instead of traditional wooden or metal one. With enough resources and demographic dividends in Latin America, the plastic household products market is also booming, and Xplast is one of the leading manufacturers. As the 1st supplier in Paraguay, Xplast produces various indoor/outdoor tables and chairs, furniture, storage cabinets, and toys, etc. Since 2012, it has purchased more than 65 FCS Servo Hydraulic injection machines (HT series) with clamping force of 50 tons to 1,000 tons, providing various products for large shopping malls and hotels in Latin America.

> See what FCS injection molding machines producing in Xplast

> Injection machine(HT) used by XPLAST

The most popular leading brand of houseware products and furniture in Taiwan - KEYWAY, has 40 FCS two-platen injection molding machines (LM series) which are producing 24 hours every day, and exports products to more than 40 countries. Moreover, KEYWAY has ordered one FCS two-platen injection molding machine in 2019 with the largest 4,000 tonf clamping force, which was successfully delivered for producing the largest plastic bathtubs in Taiwan.

> FCS installed its largest two-plateninjection molding machine in KEYWAY

> Two-platen Injection molding machines for products with greater depth LM Series

In India, there is a leading contract manufacturer and exporters of Toys, Model Hobby Kits and Sport Equipment's, which achieved revenue of Rs 200 Crore (USD 30 Million) with over 70% of revenue coming from exports to US, UK and European brands.

Its 4 factories have installed more than 200 sets of FCS servo energy-saving injection machines, and which for its new plant in 2020 were delivered directly from FCS India plant in Ahmedabad, helping the customer keep expanding its production scale.

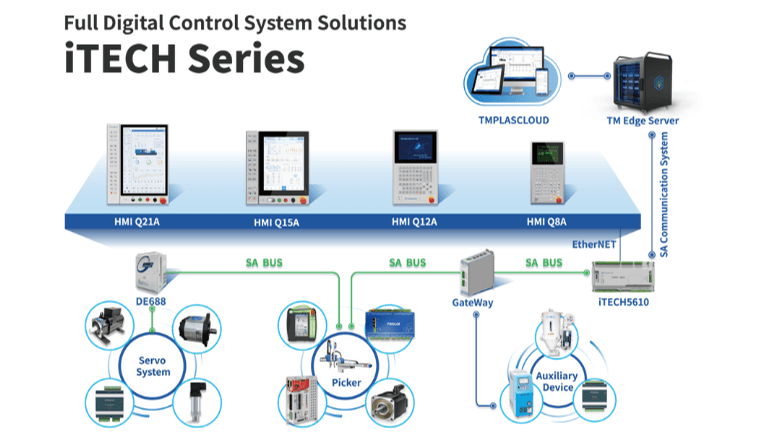

In addition to the high-end market and new process applications, FCS has been optimizing standard machines. Since 2018, it launched the advanced servo hydraulic machine (FA series) and all-electric injection molding machine (CT-e series), which are capable for industry 4.0 technology integration to achieve smart manufacturing and help improve production efficiency.

Official Website: www.fcs.com.tw

Contact Person: Manager, Mr. Hank Wu

E-mail: [email protected]

The trend of plastic products are closely related to end-users demand. The increasing demand for low-cost, lightweight, and durable purpose is driving end-users to adopt plastic furniture instead of traditional wooden or metal one. With enough resources and demographic dividends in Latin America, the plastic household products market is also booming, and Xplast is one of the leading manufacturers. As the 1st supplier in Paraguay, Xplast produces various indoor/outdoor tables and chairs, furniture, storage cabinets, and toys, etc. Since 2012, it has purchased more than 65 FCS Servo Hydraulic injection machines (HT series) with clamping force of 50 tons to 1,000 tons, providing various products for large shopping malls and hotels in Latin America.

> See what FCS injection molding machines producing in Xplast

> Injection machine(HT) used by XPLAST

The most popular leading brand of houseware products and furniture in Taiwan - KEYWAY, has 40 FCS two-platen injection molding machines (LM series) which are producing 24 hours every day, and exports products to more than 40 countries. Moreover, KEYWAY has ordered one FCS two-platen injection molding machine in 2019 with the largest 4,000 tonf clamping force, which was successfully delivered for producing the largest plastic bathtubs in Taiwan.

> FCS installed its largest two-plateninjection molding machine in KEYWAY

> Two-platen Injection molding machines for products with greater depth LM Series

In India, there is a leading contract manufacturer and exporters of Toys, Model Hobby Kits and Sport Equipment's, which achieved revenue of Rs 200 Crore (USD 30 Million) with over 70% of revenue coming from exports to US, UK and European brands.

Its 4 factories have installed more than 200 sets of FCS servo energy-saving injection machines, and which for its new plant in 2020 were delivered directly from FCS India plant in Ahmedabad, helping the customer keep expanding its production scale.

In addition to the high-end market and new process applications, FCS has been optimizing standard machines. Since 2018, it launched the advanced servo hydraulic machine (FA series) and all-electric injection molding machine (CT-e series), which are capable for industry 4.0 technology integration to achieve smart manufacturing and help improve production efficiency.

Official Website: www.fcs.com.tw

Contact Person: Manager, Mr. Hank Wu

E-mail: [email protected]

Author:FU CHUN SHIN MACHINERY MANUFACTURE CO., LTD.

FCS Group, based in Taiwan, was established 40 years ago and is well known in Asia as a quality manufacturer of machinery, offering several lines of injection molding machines and other specialty and customized equipment. In addition to the main factory and development center near Tainan, Taiwan, FCS has two additional factories in China. The company is the only injection molding manufacturer publicly traded on the Taiwan stock exchange.