Your Innovative Extrusioneers from PLASCO

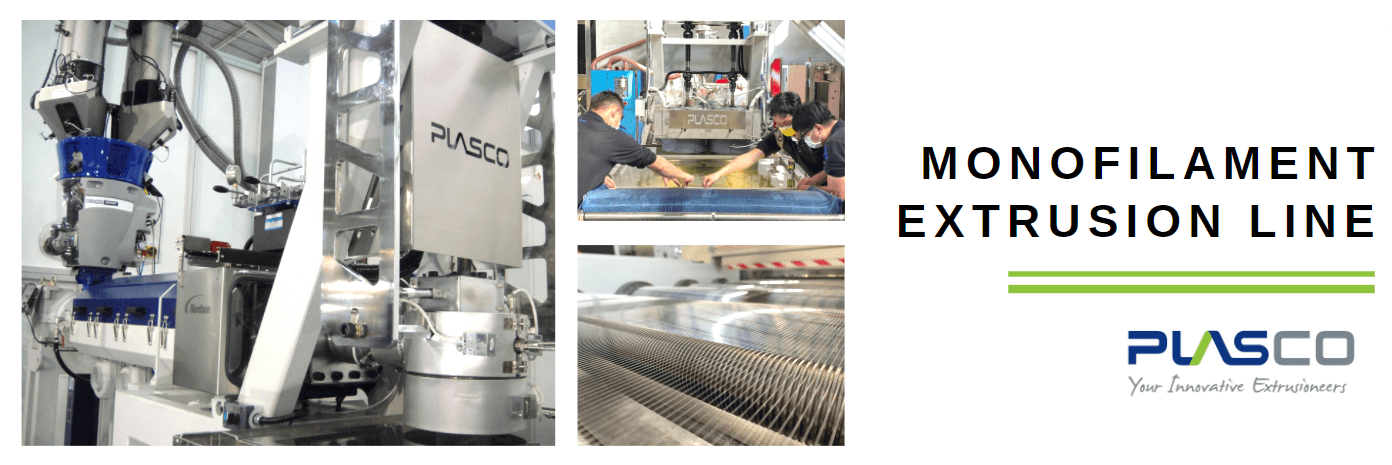

MONOFILAMENT Extrusion line

PLASCO Manufactures monofilament extrusion lines as one of their signature equipment among their broad spectrum in the plastics industry. Monofilament are used in almost our everyday life in various form, it is widely preferred in various applications due to its flexibility, good shock strength, and cost-effectiveness. The monofilament products is commonly used in fishing & agriculture net, ropes, fabrics, filters, textile conveying belts, medical devices, wastewater treatment, stretched tape, and sports strings.

PLASCO has over 30 years of experience manufacturing monofilament extrusion line to the global market, offering customers ideal process system to capture the ever-demand market, enhance profitability, and sharpen customers’ competitive edge.

PLASCO monofilament extrusion line offers complete spectrum of possibilities, with various models available for processing nylon, polyester, and polyolefins (HDPE & PP). From standard monofilament line configuration to custom-made equipment for heavy gauge monofilament, bi-co (bi-component) monofilament, crimpled monofilament, with different shape profile and diameter range from Ø 0.08mm to Ø 4.0mm for all domestic, fishery, agriculture, packaging, and various industrial application.

With the growing demand for global monofilament production, PLASCO monofilament extrusion line has advantage offers technologies, innovation, and knowhow providing customers reliable and extremely efficient production to facilitate the ever-demand requirement of all market sector, ensures the modest investment compared with its high productivities to meet and exceed each individual customers.

STRAPPING BAND Extrusion Line

PLASCO Strapping Band extrusion line is capable to produce strap sizes of all international standards for both PP and PET strap, from the narrow 5mm strap to the customized heavy gauge 25mm strap; From the standard PP strapping line configuration to the technical PET strapping line set up; For both emboss or non-emboss; Hand grade and automatic machine grade; PLASCO strapping band extrusion line has the solution for various capacity requirement from 700 tons/year and up to 3,000 tons/year.

PLASCO strapping band extrusion lines offer a combination of efficient, reliable, and performance, and guarantees:

Simplicity

Supported by user-friendly HMI control panel, allows monitoring and control of complete production process with simple process producer.

Reliability

Fom material handling, to take-up of finishing strap product, each process is monitored and managed by fully computerized control system ensuring the highest quality level.

Flexibility

Extrusion line can be configured for customer’s production requirement, for either PP or PET, from 5mm to 25mm, PLASCO offers the versatile solution.

Production

Various sizes of extruder are available for customer’s production capacity, from 1,000 to 3,500 tons annual capacity, PLASCO strap extrusion line ensures modest invest with highest possible production.

Quality

PLASCO strap extrusion line is designed, assembled, and fully tested in-house, with ultimate goad of producing top quality strap products that exceed customer’s demand.

Affordable

Comply with strictly safety and international standard, PLASCO strap ensuresion line guarantee quality, productivity, and reliability, all for a modest investment.

Energy Efficiency

Extrusion line modularly constructed with robust insulation design, and integrated with advanced PID technologies to maximize power saving, the complete line features low energy consumption, low maintenance cost, therefore ensure low production cost.

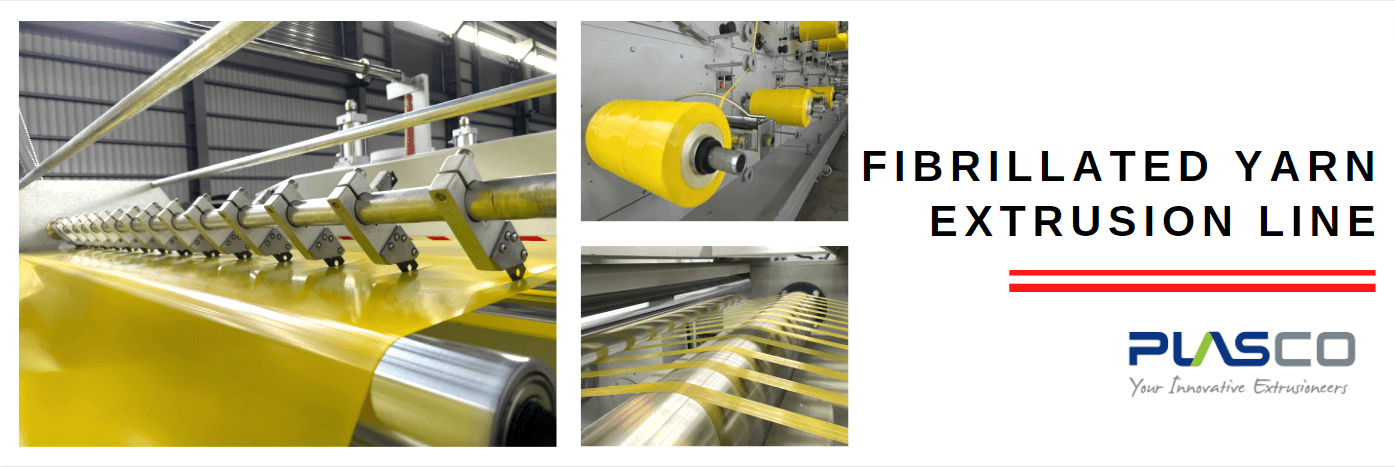

Raffia Tape & Twine Extrusion Line

PLASCO Fibrillated tape yarn extrusion line is the most flexible tape line at the forefront of the global market offering a combination of efficiency、reliability and quality performance for standard and heavy gauge tape production, fibrillated tape, and tying tape for general packaging, agricultural and various industrial application.

Tape extrusion line from PLASCO has been developed to produce PP / HDPE tape for a wide range of applications to cover the requirement of various market sectors; from the standard line specification to the special line configuration, Woven/Knitted bags, Tarpaulin, Netting, Flexible Intermediate Bulk Containers (FIBC), Baler Twine, Cable Filler, Carpet Backing, Synthetic Grass, Tying tape, Twisted Twine and many more.

We design line concept with enthusiasm, backed by extensive engineering experience, integrated with the latest proven technology, all of which with an ultimate goal to ensure each line meet highest performance and quality to exceed every customer’s demand.

With extensive series of tape lines available to cover the requirement of many market sectors, from the standard line specification to special technical line configuration, the JC-FYB/JC-BFY series tape extrusion line is the ultimate solution offering a combination of efficiency, reliability, performance, and premium quality tape product.

PLASCO Youtube ![]()

https://www.youtube.com/channel/UCt1a3S-lDtNm0SYiVrO1kIw

PLASCO Facebook ![]()

https://www.facebook.com/Plasco-Engineering-Inc-139187893310566/