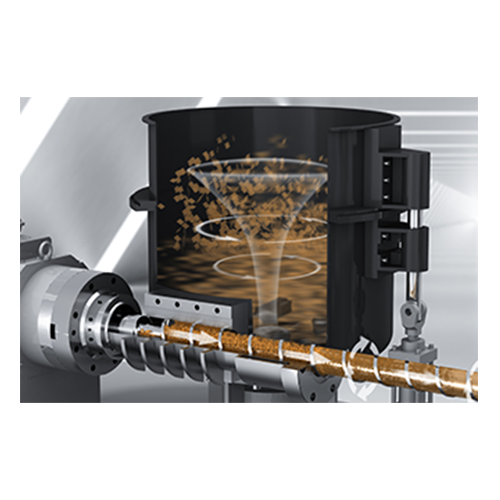

2.专用螺杆料管设计:螺杆及料筒皆为进口之材料,且经过特殊处理,其耐磨性佳,使用寿命亦较长。并依照再生原料特性,设计专属螺杆以确保能完全脱除水分与废气等杂质的功能。

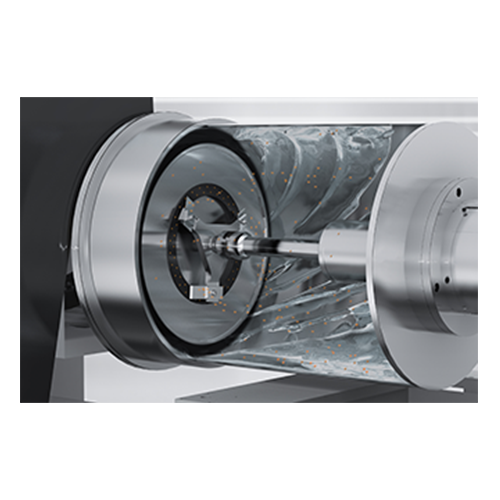

3.模头切粒可省去人工拉条的人力成本。

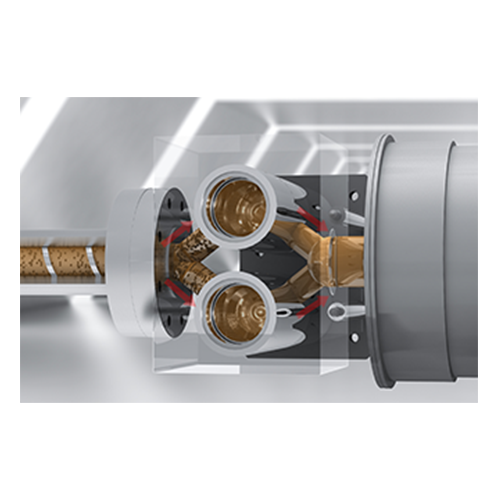

4.押出机附有压力感测计,压力过大即亮警示灯或蜂鸣器通知更换滤网。

5.单押出机型适合较干净之原料制粒,如薄膜裁切下角料、边料。

6.适用物料:PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS 等回收塑料。

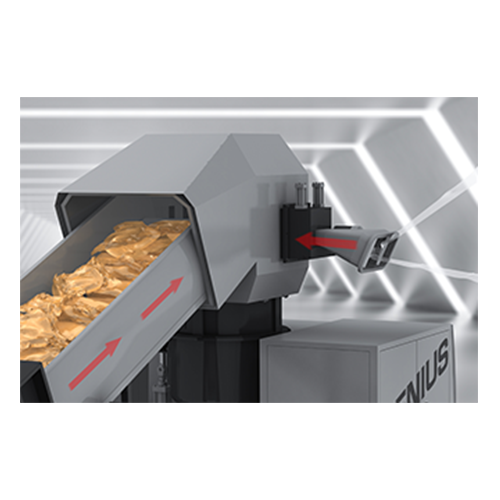

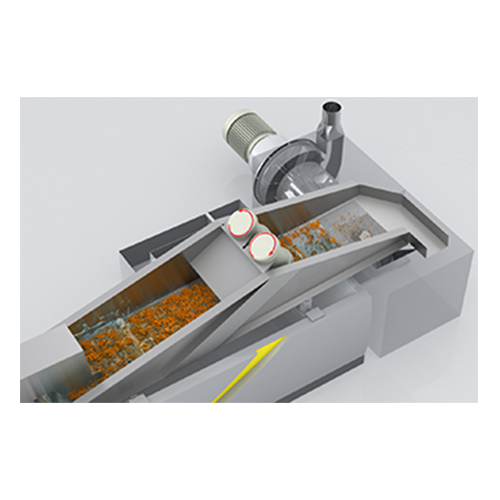

KRIEGER-150 / CUTTER COMPACTOR PLASTIC RECYCLING MACHINE / BOPP FILM / KOREA

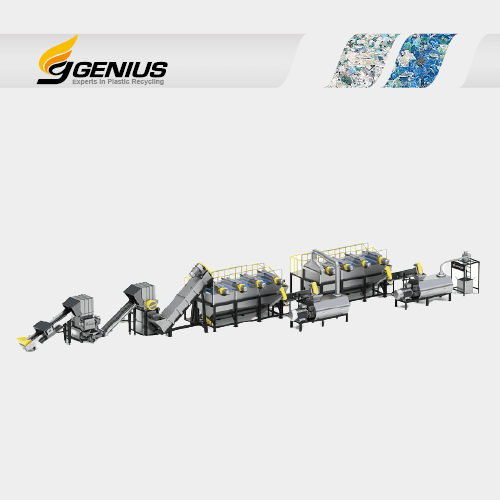

In the beginning of 2019, GENIUS installed a new Plastic Recycling machine in Korea.

The customer used to own a Korean machine with strand pelletizing system. However, its capacity only 300kg/hr. Year by year, the labor cost is becoming much higher. Due to above reasons, the customer decided to improve the efficiency of his production line.

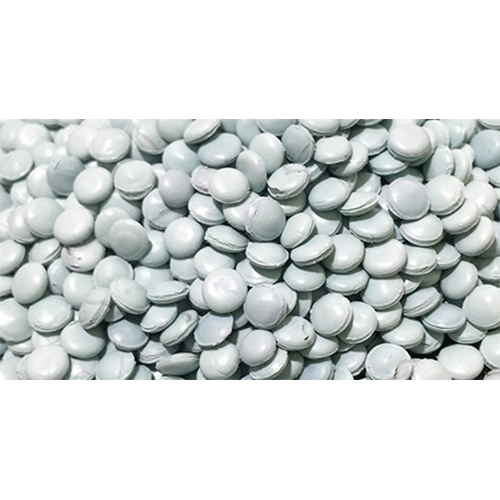

Generally, PP pellets were never been made by hot die cutting device in Korea. The customer thought it’s impossible. Therefore, the GENIUS team developed the special designed die face cutter which can pelletize sticky material.

The key point of cutting PP pellets is adjustment of cutter, but it is not easy to achieve.

With special designed universal-joint cutter, it can help to avoid the fault from manually adjustment of cutter. Compare with strand pelletizing system, the customer was surprised and satisfied that final product looks more uniform. Furthermore, not only the capacity is raised to 700kg/hr but also saved labor cost.