| Model | International Size | Theoretical Shot Volume | Clamping Force | Space Between Tie Bars | Mould Opening Stroke |

| 90BBE | 900H-326 | 183 | 90 | 360x360 | 330 |

| 120BBE | 1200H-435 | 251 | 120 | 395x395 | 380 |

| 150BBE | 1500H-614 | 366 | 150 | 425x425 | 430 |

| 200BBE | 2000H-760 | 491 | 200 | 470x470 | 480 |

| 250BBE | 2500H-958 | 641 | 250 | 515x515 | 525 |

| 300BBE | 3000H-1423 | 848 | 300 | 555x555 | 570 |

| 350BBE | 3500H-1703 | 1062 | 350 | 620x620 | 620 |

| 400BBE | 4000H-2045 | 1308 | 400 | 700x650 | 670 |

热处理的额外要素

- 固定及活动模壁加装铁板及电木板,可以绝缘并防止模具传递热源至模壁。

- 采用二段式锁模透气设计。

- 公母模温度可依成型条件作个别设定。

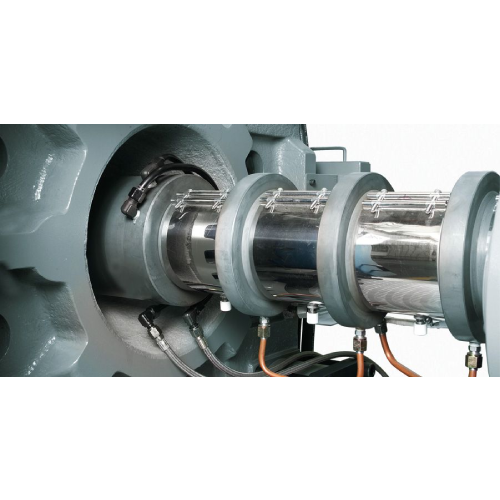

SPECIAL SCREW BARREL DESIGN FOR THERMOSET MOLDING

- Barrel sleeve is nitrified, and the screw is thermally sprayed to strengthen wear resistance and lifespan.

- One-piece rod, less L/D ratio, and compression-free screw design make melt flow smoothly.

- A linear transducer calculates the injection and plasticizing strokes and displays the correct and precise position.

- The single-carriage cylinder at the rear side provides easy access to disassemble the barrel or nozzle and to save space on the purging area.

SPECIAL SCREW BARREL DESIGN FOR THERMOSET MOLDING

- Barrel sleeve is nitrified, and the screw is thermally sprayed to strengthen wear resistance and lifespan.

- One-piece rod, less L/D ratio, and compression-free screw design make melt flow smoothly.

- A linear transducer calculates the injection and plasticizing strokes and displays the correct and precise position.

- The single-carriage cylinder at the rear side provides easy access to disassemble the barrel or nozzle and to save space on the purging area.