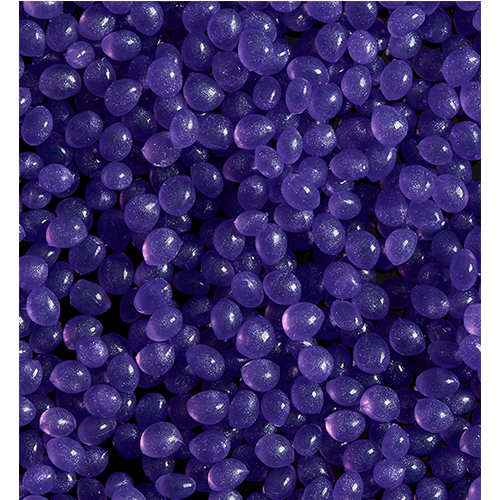

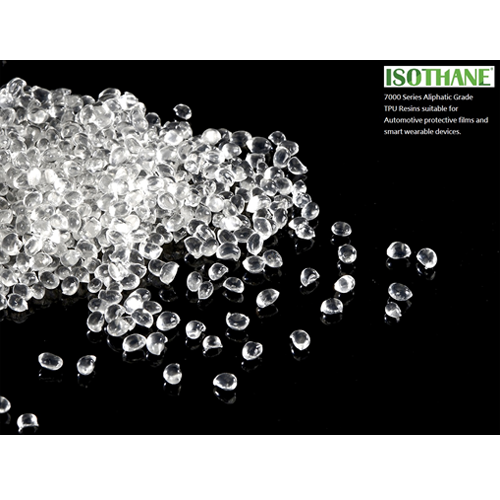

ISOTHANE TPU树脂:

创新高性能、高附加价值之绿色环保材料

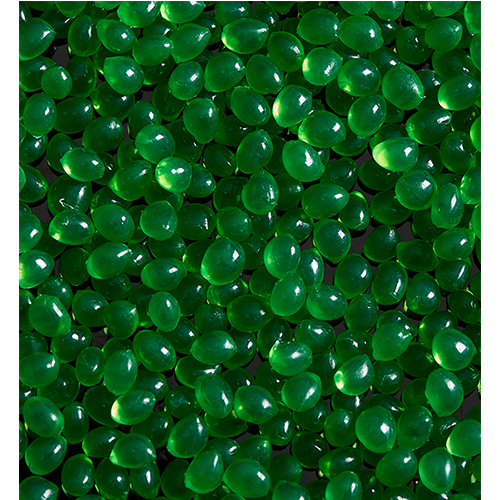

大东树脂掌握关键技术,自行研发的高性能热塑型聚氨酯弹性体,简称TPU树脂,为高级环保材料,可于土中自然分解,是优异的环保材料。具备耐磨损、耐撕裂、及耐低温曲折等特性。大东树脂TPU树脂系统发展完整,分为芳香族与脂肪族两大类。

未来轻量化与节能减碳的趋势,也成功推出以塑代钢的热塑性长纤维增强复合材料及客制化规格的树脂与复合材料等。

大东树脂推出的长纤维增强复合材料(LFRT)具有优异的刚性强度及耐冲击特性, 可取代工业零部件的金属材料,有效减轻产品重量,且成型品表面具有良好光泽度及平滑性,耐磨耗性及尺寸安定性也较一般复合材料更佳。

塑化产品生产线全程使用电脑自动化程序控制,采用先进的双轴反应押出设备产制高性能材料,并透过精密检验仪器之检测及自动化设备之包装堆栈,确保成品外观及储存品质。

| 项目名称 | High Performance Engineering TPU Composites - 长纤复材级 |

|---|---|

| 产品特性 | 优异的机械性能, 包括高刚性、耐磨耗、以及尺寸安定等, 适用于射出及押出成型之加工,可用来取代部分的热雨性材料或金属材料,以利于制成品部件的结构轻童化与设计自由度,也符合环保即可回收之要求。 |

| 应用场合 | 汽车丶手工具。 |

| 品名 | 抗张强度 | 伸长率 | 抗折强度 | 抗折模数 | 冲击强度 | 比重 | 缩收率 | 特性 & 应用 |

|---|---|---|---|---|---|---|---|---|

| 1. 聚氨酯 TPU |

高钢性 耐热性佳 尺寸稳定性优 |

|||||||

| 8102LGF40 | 1,930 (190) | 2 | 2,440 (240) | 102.000 (10000) | 29 (290) | 1.5 | 0.1~0.2 |

机械零部件 医疗器材部件 运动器材 & 鞋材部件 |

| 8102LGF50 | 2,040 (200) | 2 | 2,750 (270) | 150,900 (14800) | 30 (300) | 1.6 | 0.1~0.2 | |

| 8102LGF60 | 2,140 (210) | 2 | 2,950 (290) | 158,000 (15500) | 31 (310) | 1.7 | 0.05~0.2 | |

| 8101LGF60 | 2,140 (210) | 2 | 3,260 (320) | 183,000 (18000) | 25 (250) | 1.7 | 0.05~0.2 | |

| 2. 聚酰胺 PA |

优越的机械强度 耐热性佳 尺寸稳定性佳 |

|||||||

| NL6130 | 1,800 (176) | 2 | 2,900 (284) | 110,000 (10791) | 25 (245) | 1.35 | 0.1~0.2 |

机械零部件 医疗器材部件 运动器材 & 鞋材部件 |

| NL6140 | 2,000 (196) | 2 | 3,000 (294) | 120,000 (11772) | 30 (294) | 1.45 | 0.1~0.2 | |

| NL6150 | 2,200 (216) | 2 | 3,500 (344) | 140,000 (13739) | 40 (400) | 1.57 | 0.05~0.2 | |

| NL6240 | 2,200 (216) | 2 | 3,100 (304) | 120,000 (11776) | 20 (200) | 1.45 | 0.05~0.2 | |

| NL6250 | 2,400 (236) | 2 | 3,600 (353) | 150,000 (14720) | 32 (320) | 1.58 | 0.05~0.2 | |

| NL6340 | 2,000 (196) | 2 | 3,200 (314) | 165,000 (16192) | 30 (300) | 1.5 | 0.05~0.2 | |

| NL6350 | 2500 (245) | 2 | 3,750 (363) | 195,000 (18646) | 35 (350) | 1.59 | 0.05~0.2 | |

| NL6360 | 2,600 (255) | 1.8 | 4,000 (393) | 200,000 (19627) | 37 (370) | 1.7 | 0.05~0.2 | |

| 3. 聚丙烯PP |

优越的韧性 耐热性佳 尺寸稳定性良 |

|||||||

| PL6230 | 1,000 (98) | 2 | 1,600 (156) | 60,000 (5886) | 16 (156) | 1.12 | 0.1~0.3 |

机械零部件 医疗器材部件 汽机车零部件 |

| PL6240 | 1,100 (107) | 2 | 1,700 (166) | 85,000 (8338) | 25 (245) | 1.2 | 0.1~0.3 | |

| PL6250 | 1,250 (122) | 2 | 2,000 (196) | 110,000 (10791) | 30 (294) | 1.33 | 0.1~0.3 | |

ISOTHANE® 8101LGF60

High Performance Engineering TPU Composites Characteristics:

8101LGF60 product is long glass fiber reinforced engineering thermoplastic Polyurethanes. It exhibits excellent tensile and flexural strength, toughness, abrasive resistance, high rigidity, and maintenance of good physical properties under UV exposure. The product can be injection molded and extruded.

Properties:

The above values are shown as typical values and should not be used as specifications.

ITEMS

UNITS

TEST METHOD

VALUES

PHYSICAL

Primary Additive

%

(TGA)

60

Specific Gravity

gr./cm3

D-792

1.70

Shrinkage

%

D-955

0.1~0.2

Water Absorption,

%

24 hours at 23ºC

—

Hardness

Shore D

D-2240

90

MECHANICAL

Tensile Strength

Mpa

D-638

210

Tensile Modulus

Mpa

D-638

—

Elongation @ break

%

D-638

2

Flexural Strength

Mpa

D-790

320

Flexural Modulus

Mpa

D-790

18,000

Izod Impact Strength

J/m

D-256

(Notched 1/8”., 23 ºC )

250

THERMAL

Heat Distortion Temp.

ºC

D-648 (1.8MPa)

95

Vicat Softening Point

ºC

D-1525

190

OTHER

Flammability

UL-94

(1/8”)

HB

Processing Information:

While the above information is presented in good faith and believed to be accurate, GRECO does not guarantee satisfactory results from reliance upon such information and disclaims all liability for any loss or damage arising out of its use.

Typical Injection Molding Conditions for 8101LGF

Drying Temperature: 90~110℃(180~230℉) / 3 ~ 4 hrs.

Barrel Temperatures:

Rear Middle Front Nozzle

Melt Temperature Mold Temperature

200~210℃ (400~410℉)

220~230℃ (430~445℉)

230~245℃ (445~475℉)

240~250℃ (470~480℉)

220~250℃ (430~480℉)

95~110℃ (185~230℉)

ISOTHANE® 8102LGF

High Performance Engineering TPU Composites Characteristics:

8102LGF product is long glass fiber reinforced engineering thermoplastic Polyurethanes. It exhibits excellent tensile and flexural strength, toughness, abrasive resistance, high rigidity, and maintenance of good physical properties under UV exposure. The product can be injection molded and extruded.

Processing Information:

ITEMS

UNITS

TEST METHOD

8102LGF40

8102LGF50

8102LGF60

PHYSICAL

Primary Additive

%

(TGA)

40

50

60

Specific Gravity

gr./cm3

D-792

1.50

1.60

1.70

Shrinkage

%

D-955

0.1~0.2

0.1~0.2

0.1~0.2

Water Absorption,

%

24 hours at 23ºC

—

—

—

Hardness

Shore D

D-2240

85

87

90

MECHANICAL

Tensile Strength

Mpa

D-638

190

200

210

Tensile Modulus

Mpa

D-638

—

—

—

Elongation @ break

%

D-638

2.0

2.0

2.0

Flexural Strength

Mpa

D-790

240

270

290

Flexural Modulus

Mpa

D-790

10,000

14,800

15,500

Izod Impact Strength

J/m

D-256

(Notched 1/8”., 23 ºC )

290

300

310

THERMAL

Heat Distortion Temp.

ºC

D-648 (1.8MPa)

90

90

95

Vicat Softening Point

ºC

D-1525

180

185

190

OTHER

Flammability

UL-94

(1/8”)

HB

While the above information is presented in good faith and believed to be accurate, GRECO does not guarantee satisfactory results from reliance upon such information and disclaims all liability for any loss or damage arising out of its use.

Typical Injection Molding Conditions for 8102LGF

Drying Temperature: 90~110℃(180~230℉) / 3 ~ 4 hrs.

Barrel Temperatures:

Rear Middle Front Nozzle

Melt Temperature Mold Temperature

200~210℃ (400~410℉)

220~230℃ (430~445℉)

230~245℃ (445~475℉)

240~250℃ (470~480℉)

220~250℃ (430~480℉)

95~110℃ (185~230℉)